It is important to understand that minor scratches, dents and scuffs could occur during the construction phase.

It is important to understand that minor scratches, dents and scuffs could occur during the construction phase. These might happen whilst the cladding panels or profiles are being unpacked, during hoisting, whilst being erected or indeed by others after the cladding works have been completed. Good control of site practices will limit the amount.

Whilst the area affected by the physical damage / paint repair (where applicable) will no longer be covered by the original pre-finished steel guarantee, all areas outside the actual area of repair will continue to be covered.

If there are spare sheets / panels available of the correct lengths and the damage is severe, it is always wise (if possible, according to the design of the project and the Programme constraints) to replace damaged elements before continuing with the build. Replacement after substantial completion of the cladding works might be difficult, expensive or simply not feasible.

Minor repairs are often either not actually necessary or fairly simple and if good quality products are used, can perform well for many years.

Whilst these minor scuffs can appear unsightly, if the coating is not breached then it is often wise that these are left alone and monitored for any future breakdown. However, if left, they are usually easy to touch-up (if required) should the condition begin to deteriorate in future.

It is important to recognise that all mechanical damage is excluded from the original pre-finished steel product guarantee, whether a touch-up repair is carried out or not. On wall cladding in particular, a minor repair might be more visible than the damage itself so the decision to touch-up or not requires some thought.

Deeper scratches may cause problems if left untreated. However, an extensive paint repair is not advised. These isolated scratches through the coating should be touched in with a fine artists brush.

If the metallic coating is damaged use a zinc rich paint before applying a metal primer and a colour matched top coat and try to work within the confines of the scratch area, overlapping slightly onto the surrounding coating.

A clear 2 pack polyurethane / acrylic lacquer may be applied for added UV protection.

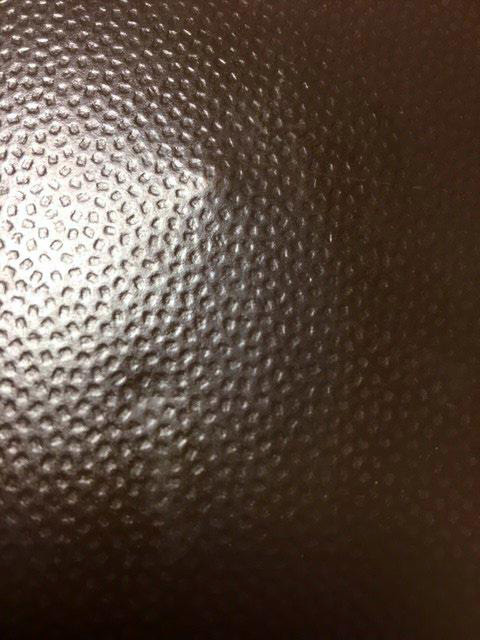

Again, minor dings and dents can look a little unsightly at close quarters but rarely impact on the overall aesthetic appeal of a building elevation.

Pre-finished steel is tested for impact resistance and will usually sustain these minor blemishes without detriment to ongoing performance. However, as with all mechanical damage, in the extremely unlikely event that these issues were to develop into a breakdown in the long term it would not be covered under any guarantee. To attempt a repair on a minor blemish can actually create a much larger and more visible issue in the long term, which would then also be exempt from the guarantee. These are usually best left alone.

Creases sometimes happen on built-up or single skin roof cladding particularly at single span areas above and below rooflights. All such mechanical damage is excluded from any guarantee. Minor creases are usually nothing to worry about.

Whilst severe creasing can look quite dramatic, the coating is rarely breached and even these usually perform ok for the full life expectancy. However, these should be monitored and touched up (if required) in future with a high build silicone or rubberised paint system. Severe creases might lead to localised water ponding, which is excluded from any guarantee and would need to be addressed urgently.

Severe damage on wall cladding, particularly on highly aesthetic flat panels and metallic colours will be very visible. These panels should be replaced during the cladding erection phase if possible.

If repairs are necessary, a proprietary epoxy filler is often used to re-establish a smooth surface before over-painting. It is important to choose a top quality 2 pack polyurethane / acrylic cladding paint. Always try to work to panel edges or a convenient ‘break line’ such as a flashing edge, which should be masked off accurately. Avoid ‘blending in’ over-spray work and always mask off straight lines. Paint the whole area with an even coating thickness.

To maintain the guarantee on the building, damaged panels should be replaced using material from the same coil and production batch wherever possible.

A number of maintenance, refurbishment and rectification methods are available within the construction market that can restore the appearance of a building and significantly extend the building’s life. Depending on the issue and the type of building, this may include the options of touch-up paints (for superficial reparation); over-cladding; a strip and repaint; or the replacement of the existing cladding. Whilst overpainting is a widely used rectification method, Tata Steel’s independent tests have shown overpainting on walls can impact the European fire standards classification. For roofs, independent testing and certification has confirmed no deterioration in fire classification, therefore overpainting on roofs can be considered as an appropriate method of reparation.

Over spraying

All over-spray repair work is excluded from the original pre-finished steel product guarantee.

The main challenges with over spraying are differential fade in the over- paint system compared to the original pre-finished steel. It is also best practice where possible to work to straight ‘break lines’ to avoid the risk of uneven colour fade. A more effective method is to mask off to the sheet overlap straight line as well as vertical straight edges within the profile lines and then apply an even coat all over the repair area. A finish coat of 2 pack clear lacquer would provide additional resistance to UV fading.

We would suggest to engage specialist sprayers with a history of such work for these cases as especially in the case of metallic shades. Consideration should be given to the possible change in reaction to fire classification after spraying.

Touch up paints

Please contact Colorcoat Connection® for touch up paint supplier information.

Related links:

Inspection and maintenance manual

Colorcoat® site guidance

Site practice

Site preparation

Site construction

Extending durability of pre-finished steel

Mechanical damage during construction

“IMPORTANT NOTICE”

While companies in the Tata Steel Europe group take care in giving out information or advice, they do so only on the basis of the facts that may be supplied (and without further investigation of them) and do not accept any liability or responsibility for providing inaccurate, misleading or incomplete information or advice or any reliance which may be placed on such information or advice. Before relying on any information or advice which Tata Steel in Europe group companies may supply (whether in this communication or otherwise), the recipient should satisfy itself of the accuracy and appropriateness of that information or advice. Please note that the Tata Steel General Conditions of Sale, which set out our liability to you, apply to all sales of Tata Steel Europe products and services to the exclusion of any other terms that a customer seeks to impose or incorporate, or which are implied by trade, custom, practice or course of dealing. The terms of the General Conditions of Sale may only be varied in writing by both parties. No information, advice or communication provided by Tata Steel Europe Limited or any of its subsidiaries to the recipient in response to a query (whether given in writing or orally) shall be deemed to vary the General Conditions of Sale."