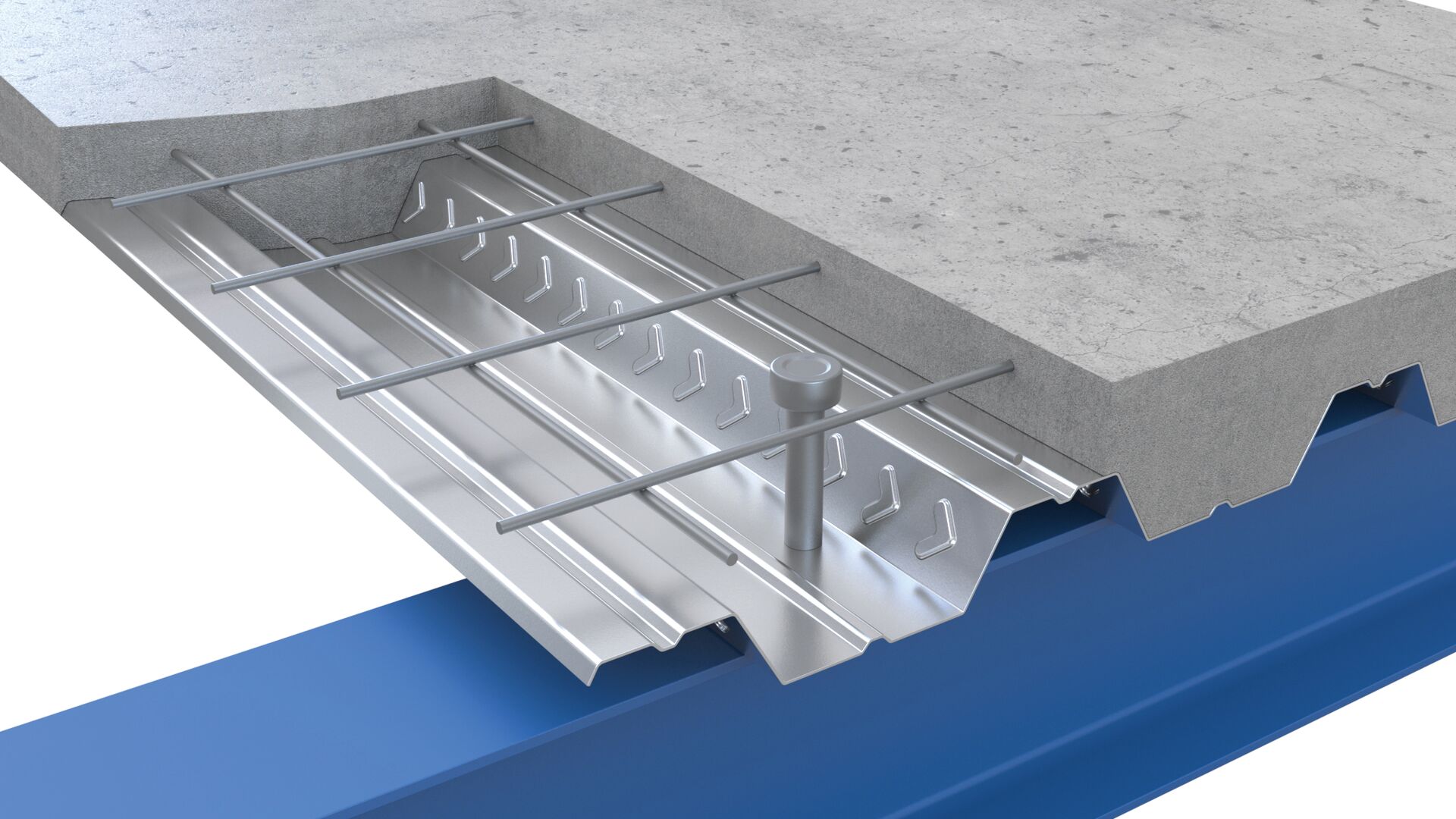

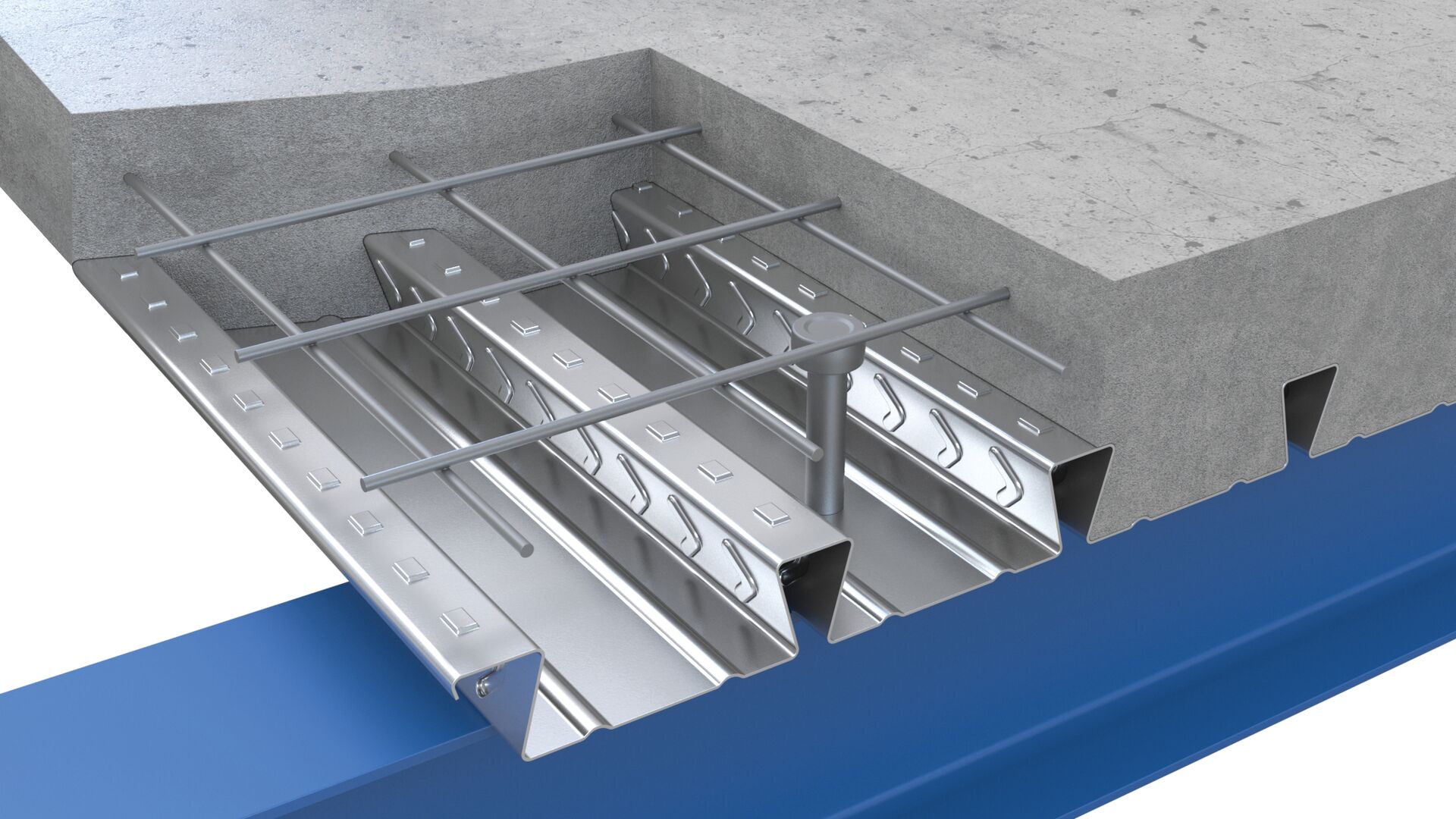

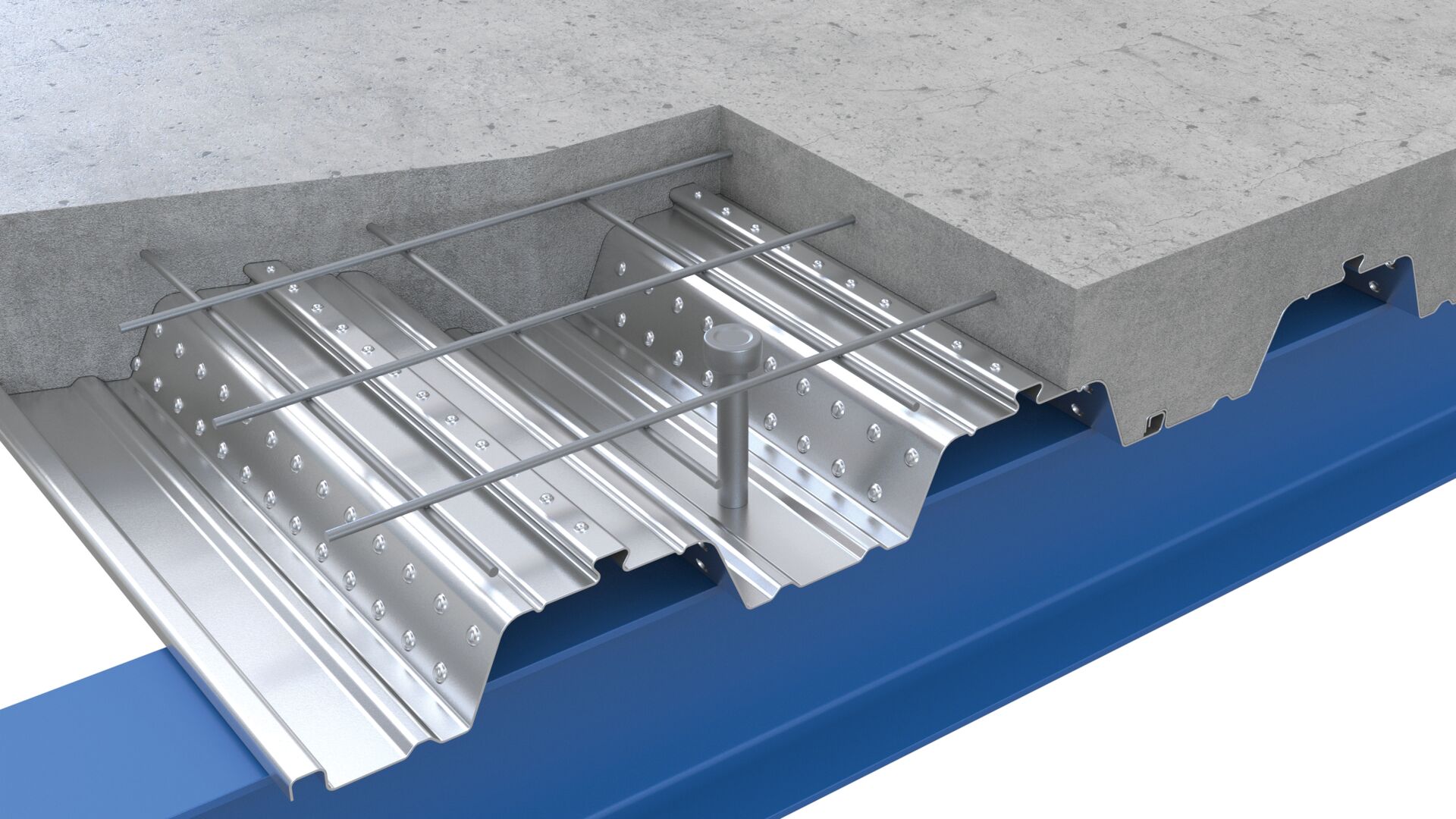

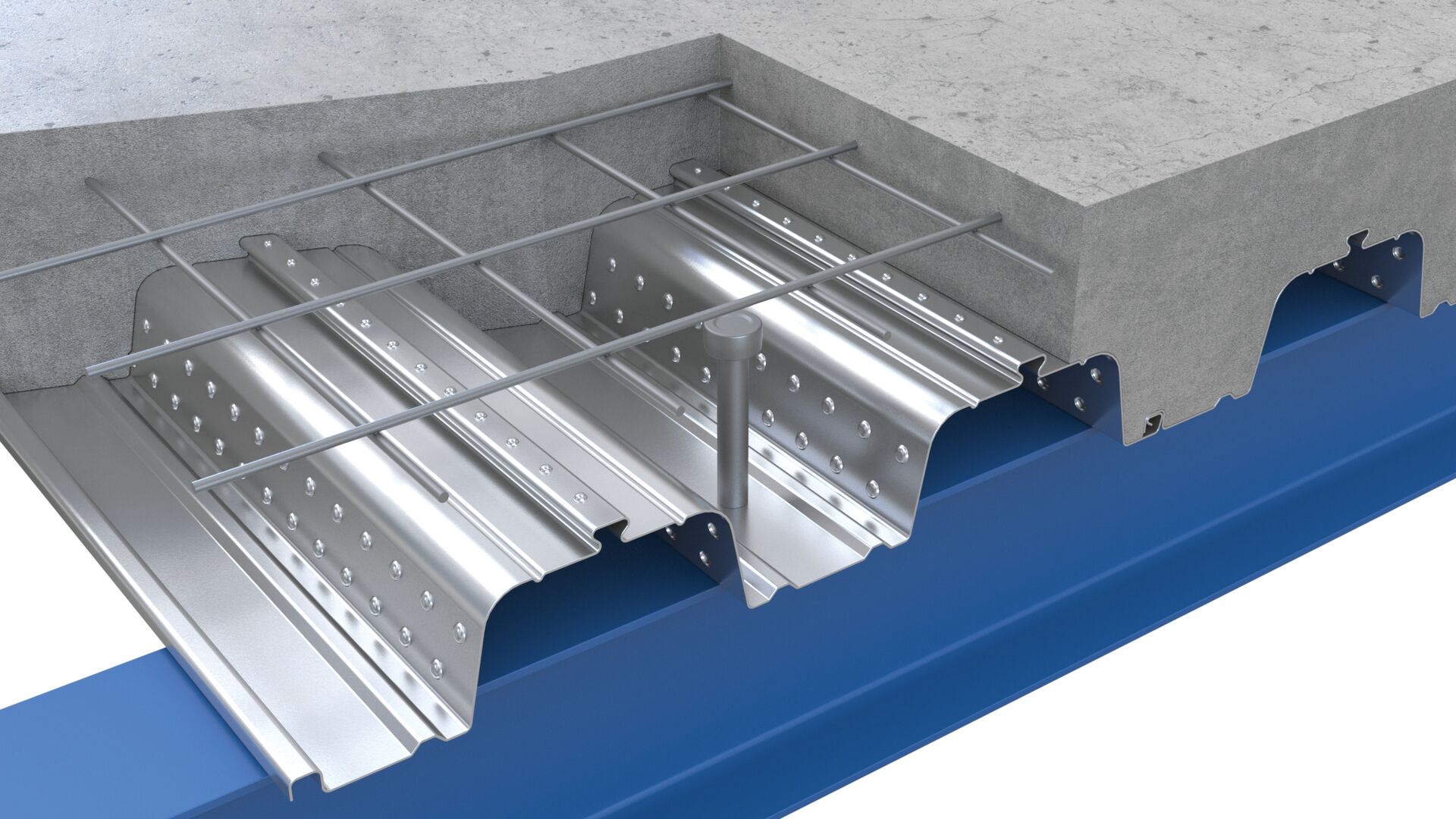

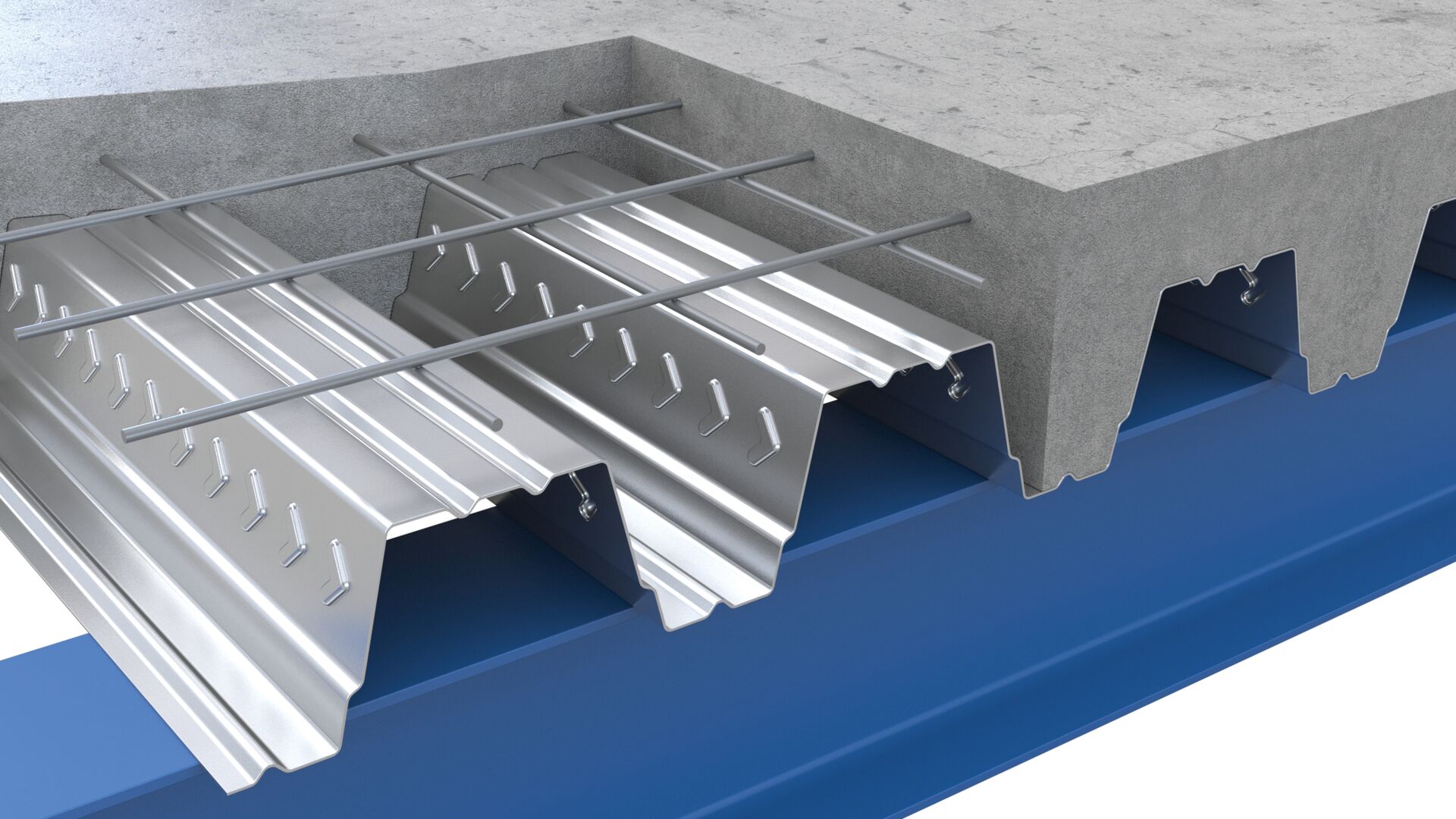

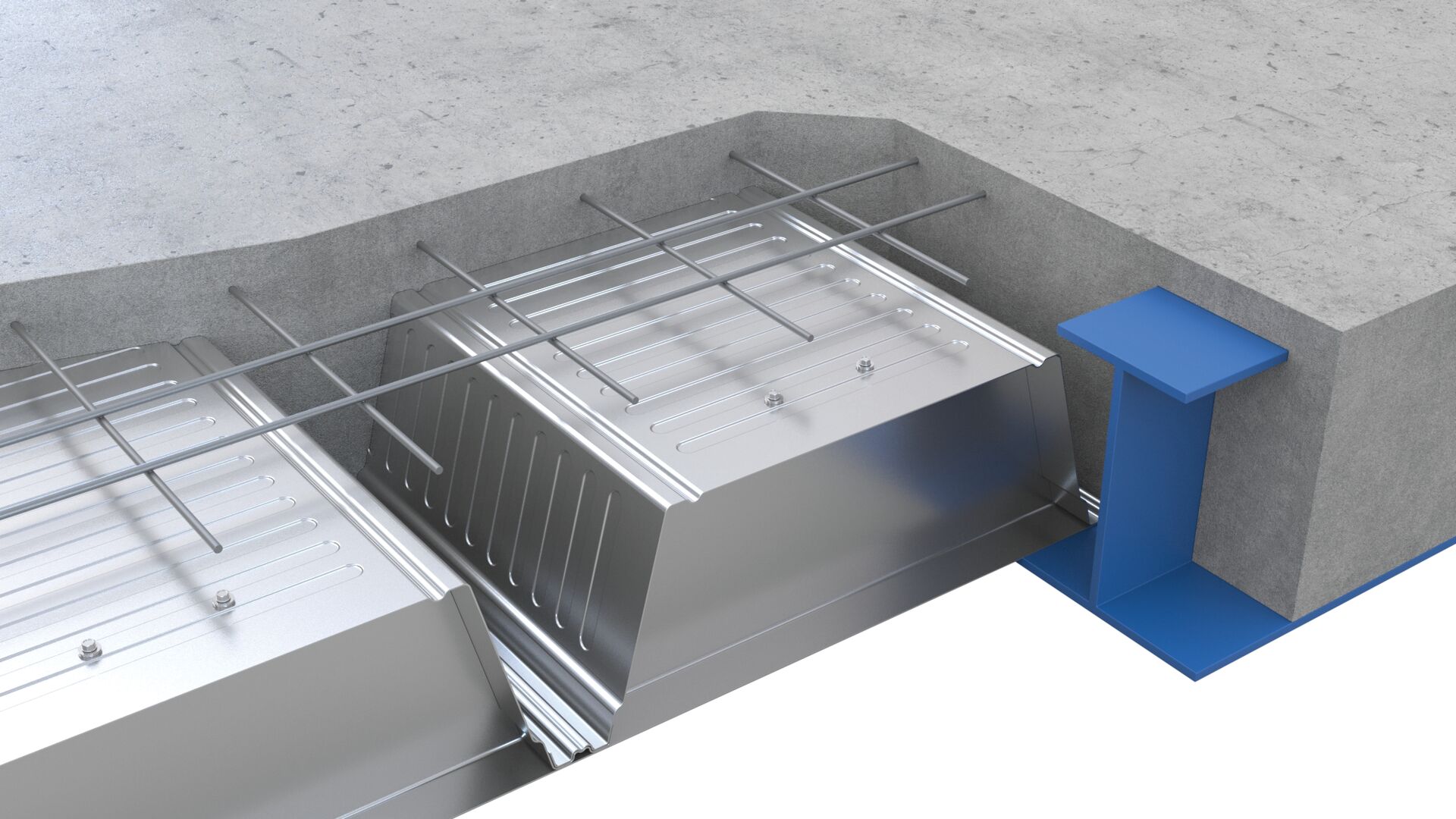

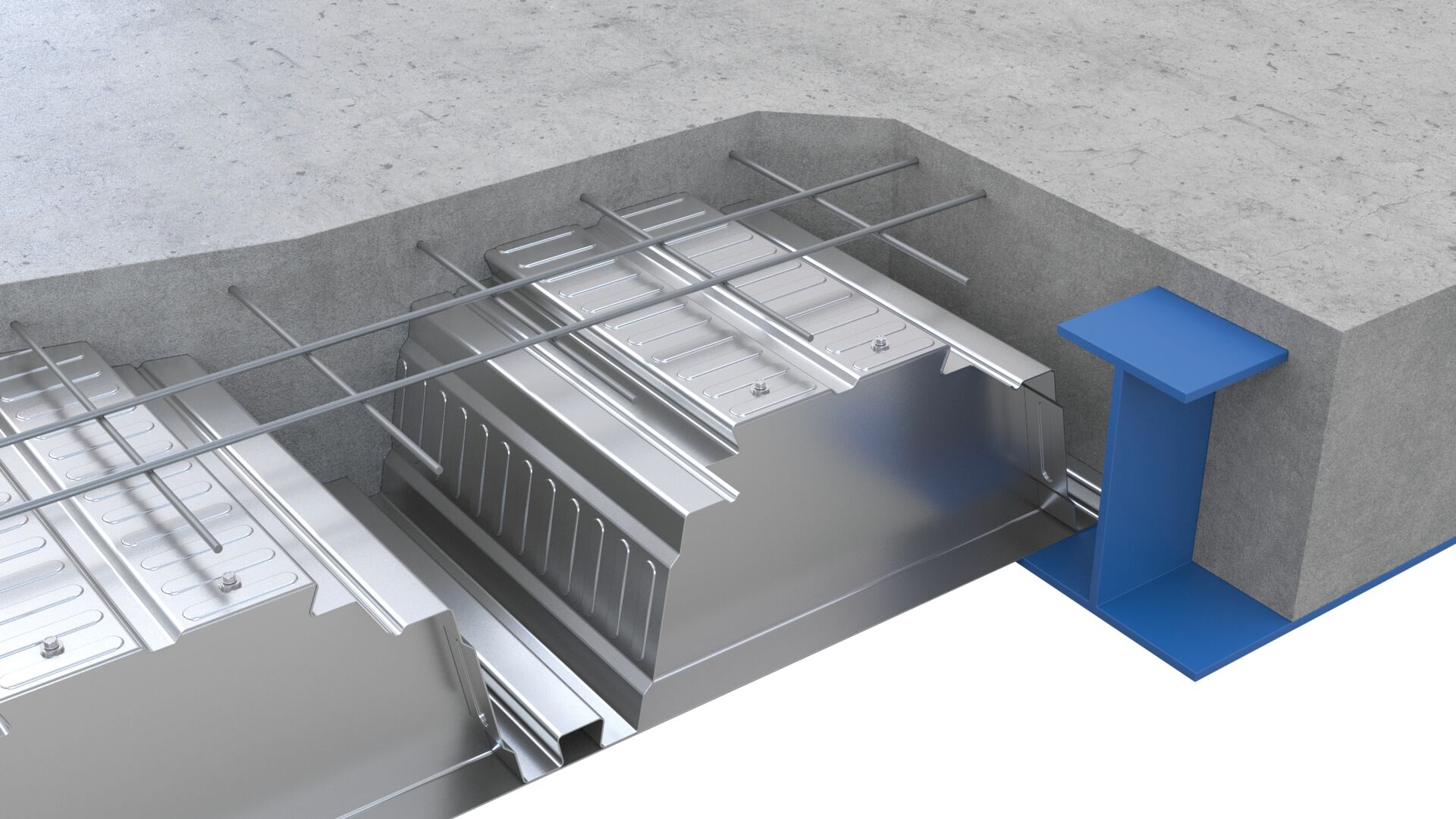

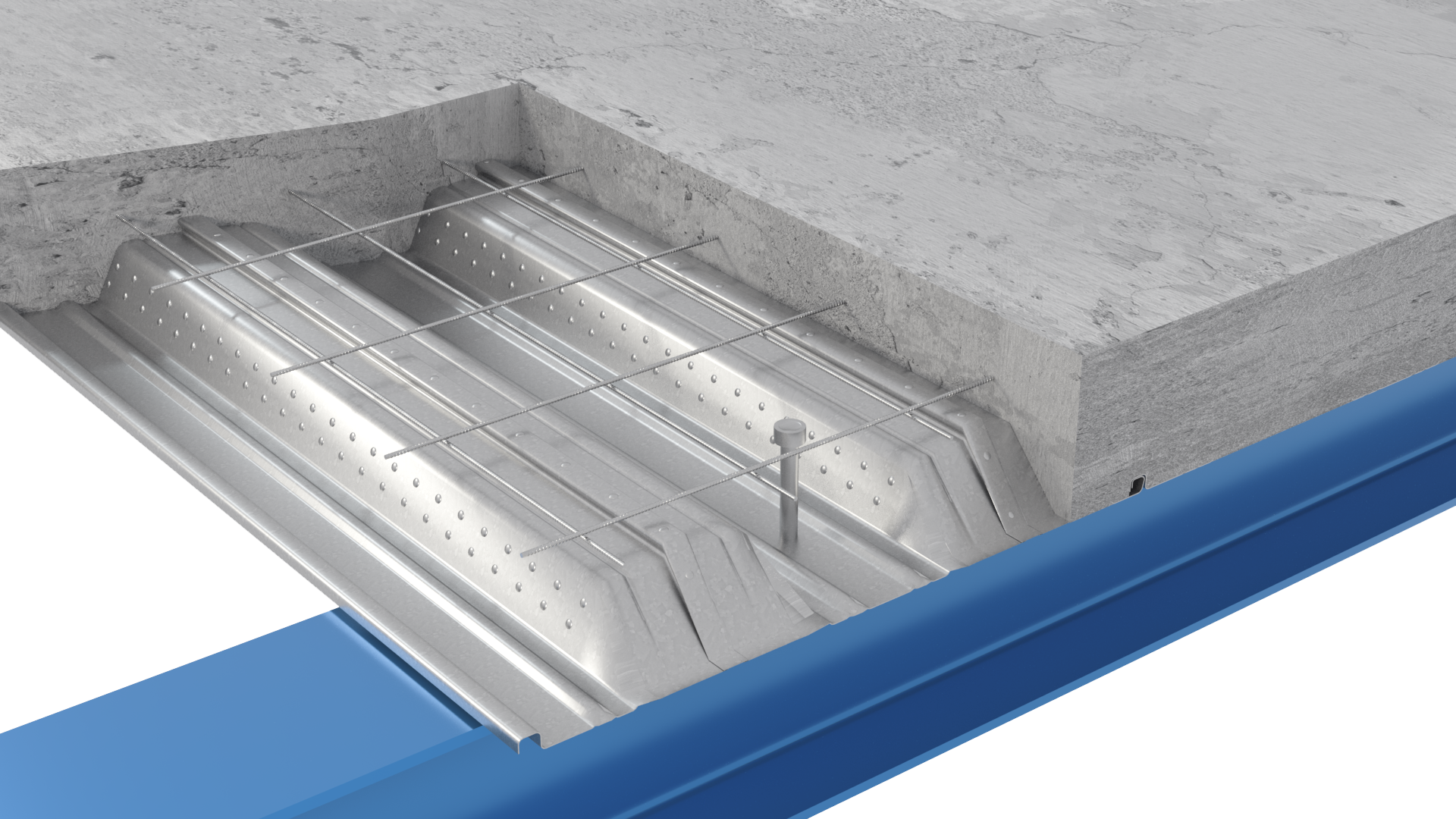

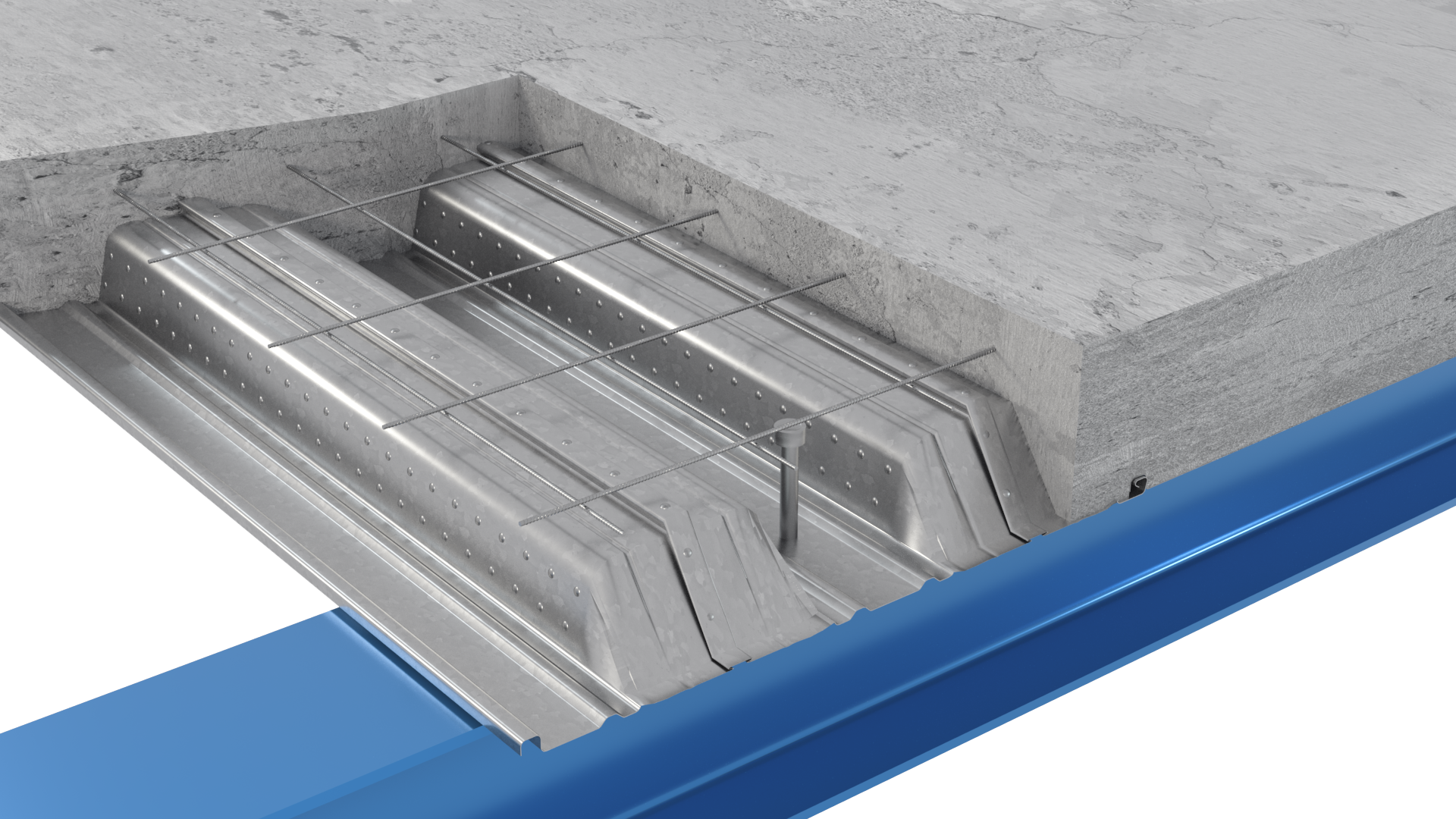

ComFlor® 80 closed ends

This engineered closed ends variant of ComFlor® 80 allows quicker and simplified on-site installation on pre-studded beams.

- Better on-site cost control

- Factory controlled stud-welding

- No filler blocks or end caps required

- Allows pre-galvanised or fully painted beams

- Enhanced acoustic and fire performance

- On-site hot work reduced or eliminated

- Closed ends control concrete leakage

Download our ComFlor® range at a glance brochure

Download our full ComFlor® technical manual

Request an EPD

Book a CPD

EN-Construction-Product-ComFlor 80-closed ends

EN-Construction-Product-ComFlor 51 | Design support - Mar25

We maintain a friendly technical help desk which is freely available to all Consulting Engineers, and Contractors to assist with all aspects of ComFlor® composite floor design. The services we offer include:

Design calculations

To assist the specifier, the team are able to provide design calculations, generally dictated by the construction stage condition, the load and span required for service and the fire resistance required for the slab. Our team can also help with specialised design issues such as point loads, requirements for anti crack mesh, openings, etc.

Vibration

ComFlor® composite floor decks can meet the most stringent vibration applications, such as those required for National Health Service operating theatres.

Software tools

Comprehensive ComFlor® Software is free to download here. The ComFlor® Software provides quick and easy calculations for different building categories, loads, fire performance, spans, vibration, point loads and line loads. Regular updates are sent to all registered users.

Supporting beam width

For all ComFlor® 46 load/span tables, the width of the support beam used is assumed to be 152mm.

Fire design

The capacity of the composite slab in fire may be calculated using two methods, either ‘Mesh and Deck Fire Method’ (mesh only and no trough bar reinforcement) or ‘Bar Fire Method’ (trough bottom bar reinforcement only with no contribution from the mesh and profile).

Specification service

Our ComFlor® team are able to provide a comprehensive specification guidance to ensure the correct composite floor specification goes into the contract documents.

In-house CPD seminars

Primarily aimed at Engineers and Architects, these free seminars last around 50 minutes, ending with a question & answer session and are delivered by our experienced regional teams. Topics include:

- Composite floor decking in construction.

- Structural roof decking in construction.

- Steel building envelope systems for non-domestic buildings.

- Factory tour – Insulated Panel Line at Shotton works.

For full technical information download our ComFlor® manual

EN-Construction-Product-ComFlor 80 closed ends | Design Information

ComFlor® 80 Composite slab - volume and weight (EC values)

| Weight of concrete (kN/m2) | |||||

| Slab depth (mm) | Concrete volume (m3/m2) | Normal weight concrete | Lightweight concrete | ||

| Wet | Dry | Wet | Dry | ||

| 130 | 0.085 | - | - | 1.70 | 1.62 |

| 140 | 0.095 | 2.38 | 2.28 | 1.90 | 1.81 |

| 150 | 0.105 | 2.63 | 2.52 | 2.10 | 2.00 |

| 160 | 0.115 | 2.88 | 2.76 | 2.30 | 2.19 |

| 170 | 0.125 | 3.13 | 3.00 | 2.50 | 2.38 |

| 180 | 0.135 | 3.38 | 3.24 | 2.70 | 2.57 |

| 190 | 0.145 | 3.63 | 3.48 | 2.90 | 2.76 |

| 200 | 0.155 | 3.88 | 3.72 | 3.10 | 2.95 |

| 210 | 0.165 | 4.13 | 3.96 | 3.30 | 3.14 |

| 220 | 0.175 | 4.38 | 4.20 | 3.50 | 3.33 |

| 230 | 0.185 | 4.63 | 4.44 | 3.70 | 3.52 |

| 240 | 0.195 | 4.88 | 4.68 | 3.90 | 3.71 |

| 250 | 0.205 | 5.13 | 4.92 | 4.10 | 3.90 |

Notes

1. Deck and beam deflection (ie, ponding) is not included in the table.

2. Deck and mesh weight is not included in the weight of concrete figures.

3. Eurocode density of concrete is taken as:

Normal weight (wet) 25 kN/m3

Normal weight (dry) 24 kN/m3

Lightweight (wet) 20 kN/m3

Lightweight (dry) 19 kN/m3

ComFlor® 80 (S350) Section properties (per metre width)

| Nominal thickness (mm) | Design thickness (mm) | Cross section area (mm2/m) | Profile weight (kN/m2) | Height to neutral axis (mm) | Moment of inertia (cm4/m) | Ultimate moment capacity (kNm/m) | ||

| Sagging | Hogging | Sagging | Hogging | |||||

| 0.90 | 0.86 | 1382 | 0.11 | 44.86 | 165.42 | 156.17 | 10.76 | 8.68 |

| 1.00 | 0.96 | 1542 | 0.12 | 44.90 | 181.32 | 171.83 | 13.34 | 10.65 |

| 1.20 | 1.16 | 1864 | 0.15 | 45.01 | 213.13 | 203.16 | 18.49 | 14.59 |

Section properties in the above table conform to BS 5950.

Deck material

Tata Steel Galvatite®, hot dip zinc coated steel to BS EN 10346 S280GD+Z275, with guaranteed minimum proof strength of 280N/mm2 and zinc coating of total mass 275g/m2 (including both sides). This is sufficient for internal floors in a non-aggressive environment, which satisfies the requirement in clause 4.2 BS EN 1994-1-1 - the exposed surfaces of the steel decking shall be adequately protected to resist the particular atmospheric conditions. A zinc coating, if specified, should conform to the requirements of BS EN 10346. The specification may be varied, depending on service conditions.

Anti-crack mesh

As a minimum requirement where the control of crack width is of no interest, BS EN 1994-1-1, 9.8.1(2) recommends that, where continuous slabs are designed as simply-supported in accordance with BS EN 1994-1-1, 9.4.2(5), the cross-sectional area of the anti-crack reinforcement above the ribs should be not less than 0.2% of the cross-sectional area of the concrete above the ribs for un-propped construction, and 0.4% of this cross-sectional area for propped construction. The mesh specified in the quick reference Eurocode tables, complies with this clause.

Where forklift truck (or other similar concentrated loading) is expected, 0.5% minimum percentage reinforcement should be used over the supports and the previous stated percentages elsewhere to control cracking. For further information refer to SCI AD150.

In accordance with Steel Construction Institute (SCI) P300 ‘Composite Slabs and Beams Using Steel Decking: Best Practice for Design and Construction, a nominal cover of 25mm is stated for an exposure level XC1, for all concrete cylinder strengths for both normal (C25/30 to C40/50) and lightweight concrete (LC25/28 to LC32/35). This nominal cover of 25mm is the minimum cover of 15mm plus a fixing tolerance of 10mm.

Supporting beam width

For all ComFlor® 46 load/span tables, the width of the support beam used is assumed to be 152mm.

Fire design

The capacity of a composite slab with nominal anti-crack mesh in fire is calculated in accordance with Steel Construction Institute NCCI PN005 ‘Fire resistance design of composite slab’. Two fire-design methods can be used in the ComFlor® 9 software, namely ‘Mesh and Deck Fire Method’ or ‘Bar Fire Method’. For further details of the performance of composite slabs with nominal anti-crack mesh in fire, please contact the technical team.

Design support

The Technical Department at Tata Steel offers a comprehensive advisory service on design of composite flooring, which is available to all specifiers and users. Should queries arise which are not covered by this literature or by the ComFlor® 9 software, please contact us.

EN-Construction-ComFlor-Finishes-ComFlor51+Mar25

Standard Galvanised

Our whole range comes with Z275 standard galvanising as standard - this means that the steel has been coated with a layer of zinc weighing 275 g/m² on both sides of the steel (the total mass of zinc). This is applied by hot-dip galvanizing, where the steel is dipped into molten zinc to form a durable and protective layer.

MagiZinc® 140

MZ140 products deliver a 37% reduction in coating CO2 when compared with Z275 galvanised coating. The coating process for our MZ products requires fewer resources but delivers improved product performance.

MagiZinc® 310

MZ310 products deliver a 37% reduction in coating CO2 when compared with Z275 galvanised coating. The coating process for our MZ products requires fewer resources but delivers improved product performance. This is a premium product delivering further enhanced durability over the whole life of your project.

FD+

Our ComFlor® FD+ composite steel floor decking with Colorcoat Prisma® is a solution that has been developed and optimised for floor deck applications. The Colorcoat Prisma® finish provides a highly durable solution for onerous environments backed by our multi decade guarantee. Available in both ComFlor® 60 and 80 variants for use in up to C5 environments and coastal applications and backed by a multi-decade guarantee.

| Profile | Gauges available (mm) | Steel grade | Finishes | ||||||

0.7 | 0.9 | 1.0 | 1.2 | 1.25 | MZ140 | MZ310 | FD+ | ||

| ComFlor® 46 | - | ✔ | - | ✔ | - | 280 | ✔ | ✔ | - |

| ComFlor® 51+ | - | ✔ | ✔ | ✔ | - | 350 | ✔ | ✔ | - |

| ComFlor® 60 | - | ✔ | ✔ | ✔ | - | 350 | ✔ | ✔ | ✔ |

| ComFlor® 60 Closed Ends | - | ✔ | ✔ | ✔ | - | 350 | ✔ | ✔ | - |

| ComFlor® 80 | - | ✔ | ✔ | ✔ | - | 350 | ✔ | ✔ | ✔ |

| ComFlor® 80 Closed Ends | - | ✔ | ✔ | ✔ | - | 350 | ✔ | ✔ | - |

| ComFlor® 100 | - | ✔ | - | ✔ | - | 280 | ✔ | ✔ | - |

| ComFlor® 210 | - | - | ✔ | - | ✔ | 350 | ✔ | ✔ | - |

| ComFlor® 225 | - | - | - | - | ✔ | 350 | ✔ | ✔ | - |

For full technical information download our ComFlor® manual

EN-Construction-Product-ComFlor-range-low-carbon-options-ComFlor

BES 6001 Responsible Sourcing

Building Systems UK operations, supply chain and products are certified under the BRE Responsible Sourcing Framework Specification BES 6001. We are able to help our customers to operate more sustainably by providing guidance on the specification of our products and the impact on obtaining credits under building certification schemes such as BREEAM.

Find out more about responsible sourcing

Environmental Product Declarations (EPDs)

Building Systems UK’s vision is to ‘enable the creation of sustainable spaces where we live work and play’. As a manufacturer we have a duty to operate responsibly and in a transparent way. Building Systems UK are one of the most transparent and reported construction product manufacturers in the UK, with a unique offering of project specific and bespoke Environmental Product Declarations. This is enabled by our unique operatorship of an Environmental Product Declaration Programme.

Find out more about EPDs and request your project specific EPD

Optemis® Carbon Lite

Optemis Carbon Lite is a fully certified in-setting scheme verified by leading assurance organisation DNV. Our continued commitment to decarbonisation means reductions in CO2 emissions can now be passed on to our customers, enabling them to achieve immediate Scope 3 emission savings.

Revenues generated from the sale of Optemis Carbon Lite certificates are used to fund additional projects, generating further CO2 savings to be verified by DNV and speeding up our decarbonisation efforts.

Find out more about Optemis Carbon Lite

For full technical information download our ComFlor® manual

EN-Construction-Product-ComFlor-range-specification-software

Using the ComFlor software is an efficient way to determine suitable solutions for your flooring needs. Click here to download.

The software enables you to enter profile, spans, slab depth, loadings (including line loads and point loads) and fire requirements plus can check for additional reinforcement, propping or using fibres, giving you a several page output confirming the suitability of your design.

Design principles are in accordance with the appropriate parts of BS 5950 : Part 4 (1994), Part 6 (1995), Part 8 (1991) For design to the Eurocodes, the design principles are in accordance with EN 1994-1-1 and EN 1994-1-2:Eurocode 4. The design checks performed by the program cover the construction stage, the normal design stage and fire.

To download ComFlor® 9.0.34 software for the Middle East only

A version of this software, using customary dimensions for the Middle East market, is available to download here.

For full technical information download our ComFlor® manual

EN-Construction-NBS-specification-tab-comflor

For full technical information download our ComFlor® manual

EN-Construction-Product-ComFlor 80 closed ends | Downloads

Downloads

EN-Construction-Brochure-ComFlor at a glance

ComFlor® range at a glance

EN-Construction-Brochure-MagiZinc - the innovative replacement for conventional galvanised steel

MagiZinc - the innovative replacement for conventional galvanised steel

EN-Construction-Brochure-ComFlor manual

ComFlor® manual

EN-Construction-Download-EPD-Tata Steel EPD ComFlor 80 1.0mm with FD170

Building Systems UK EPD ComFlor® 80 1.0mm with FD170

EN-Construction-Download-EPD-Tata Steel EPD ComFlor 80 0.9mm

Building Systems UK EPD ComFlor® 80 0.9mm

EN-Construction-Certificate-BES6001-UK products

BES 6001 Certificate UK products

EN-Construction-Product-ComFlor-range-Range-at-a-glance

ComFlor® 60 closed ends

- 600mm cover width

- 60mm depth

- 300mm profile pitch

- Max Span:

Single 3940mm / Double 4700mm

ComFlor® 80 closed ends

- 600mm cover width

- 80mm depth

- 300mm profile pitch

- Max Span:

Single 4340mm / Double 4970mm

For full technical information download our ComFlor® manual

EN-Construction-Contact-BSUK envelope

Building Systems UK technical team - Building Envelope