For the construction industry to meet its goals of better sustainability and a safer built environment, it must continue to pursue digitalisation. Better data management and information sharing has already begun to demonstrate some of the potential benefits of digitalisation, mainly through efficiency and productivity improvements.

To unlock those benefits fully will mean going beyond BIM and 3D CAD, embracing new digital platforms and ways of thinking about construction. Working together, manufacturers, specifiers and installers can better understand how building envelopes perform, while accelerating the movement towards the golden thread of information, and wider adoption of the circular economy.

Using data to understand the performance of building envelope systems

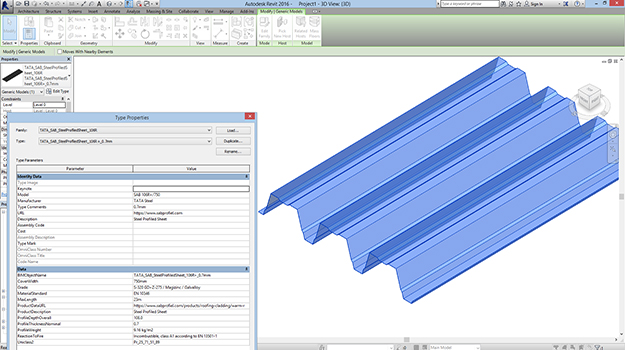

Using BIM and 3D CAD has demonstrated productivity and efficiency improvements across the construction industry, and has also helped to reduce waste. However, for these improvements to be realised to the fullest possible extent, they need to be part of linked, traceable data that sits with materials and products throughout the supply chain and throughout construction projects.

For initiatives like the golden thread and digital twins to work, the construction industry needs – and is starting – to move away from generic product data. Instead, information should communicate the specific configuration and performance characteristics of building envelope products or systems.

When data reflects a product’s manufacture (including responsible sourcing), the environmental impact of its manufacture (such as through the availability of an environmental product declaration), how it was installed, and how it can be taken apart again, then the information becomes more useful.

Once a building is operational, the next step will be to use sensors to capture in-use data. For example, in-situ measurement of thermal transmittance could establish if, and how, heat loss through the building envelope changes over time. It will also be possible to understanding how the coating of cladding panels degrades due to UV exposure.

This type of in-use data will support maintenance, refurbishment and, where necessary, replacement of building envelope products over the life of the building. It will also make it more likely that products are reused at the end of a building’s life, aiding the implementation of circular economy principles.

Products can’t be reused if there is no record of how they’ve been maintained and refurbished, and that record can only exist if useful data is captured. Similarly, buildings can’t be disassembled for components to be reused if there is no record of how to retrieve a component so that’s ready to be moved on to the next project.

About Tata Steel and the COMBINED platform

Tata Steel is committed to developing new capability – such as unique product marking, and tagging and tracking products – that will drive improvements in digitisation across the construction industry.

Existing tools have already supported a shift towards more efficient and productive ways of working, and continue to assist designers and specifiers in meeting sustainability requirements. For example, the COMBINED platform allows users to configure system build-ups for non-domestic buildings, selecting from the complete range of Tata Steel building envelope products.

The platform provides the necessary information to quickly assess the most efficient way to meet project performance requirements. A key part of ensuring that digitisation is embraced and adopted is giving people who need data the reassurance that it is up to date, and reflects any changes made by the manufacturer.

Tata Steel has sought to build trust in the COMBINED platform by maintaining and updating the product data available in the tool. Learn more about the COMBINED platform and BIM objects from Tata Steel.