For roof designs involving acoustics, there is a trade off between the requirements for acoustic absorption and reduction.

For roof designs involving acoustics, there is a trade off between the requirements for acoustic absorption and reduction. Roof decks may be perforated in the web to assist absorbtion, however the following points should be noted:

- The structural capacity of the deck is reduced, requiring closer support centres.

- The perforated open area allows sound to escape into the roof cavity, thus lowering acoustic reduction values. This can be overcome by the introduction of dense acoustic mat layers above the deck, but at an increased overall cost.

How then can these conflicting requirements be achieved?

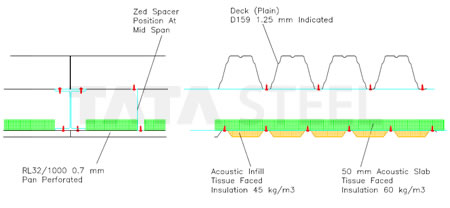

One solution is to install a plain deck with a perforated under lining sheet, as indicated:

RoofDek D159 perforated within the profile web, provides 7.6% open area. Ideally the larger the open area the more sound will be absorbed. By perforating the deck there is a loss of structural strength, thus reducing maximum spanning capability.

Installation of RoofDek D159 1.25mm gauge plain deck provides maximum spanning capability, adding mass which assists acoustic reduction values.

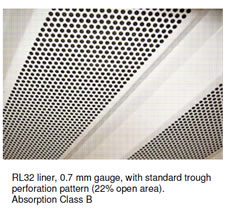

The addition of RL32/1000 perforated under liner improves absorption values with 22% open area, with a standard perforated pattern.

There would however be additional costs for supporting zed spacers, additional fasteners and installation time. However the benefits of enhanced acoustic absorption and reduction and improved aesthetics will compensate for this.

RL32/1000 liner profile can be supplied:

- With standard perforation pattern to achieve absorption

Class B. - Coated plain finish ie, non perforated, where acoustic absorption is not required, for enhanced aesthetics to

hide all support steelwork.