As with roof systems, sealants and fillers are one of the key components essential in providing adequate waterproofing protection to safeguard the building from the elements, making it water resistant and air-tight, whist complimenting the duration of the system guarantee.

Following our last blog Part 1: The importance of sealants and fillers in weatherproofing roof built-up systems, we bring you Part 2: The importance of sealants and fillers in weatherproofing wall built-up systems.

As with roof systems, sealants and fillers are one of the key components essential in providing adequate waterproofing protection to safeguard the building from the elements, making it water resistant and air-tight, whist complimenting the duration of the system guarantee.

It is critical, consideration is given to sourcing and specifying good quality sealants and profiled fillers that provide adequate warranty and life expectancy on all joints, openings, end and side laps – after all they need to be versatile enough to provide waterproofing protection to keep out rainwater, snow, hail, wind, moisture, insects, small birds, etc, and at the same time improve energy efficiency.

We work closely with reputable high-end sealant and profiled filler manufacturers who produce specific materials to complement our Trisobuild® systems providing a waterproofing barrier that will protect your wall cladding system for the lifespan of the building.

The following information has been extracted from our updated and details the guidance we provide on sealants and fillers for wall cladding applications. The sealants and fillers we reference are from reputable suppliers and are recommended for use alongside our Trisobuild® systems.

When laying butyl strip sealants (PIB) attention must be drawn to the following:

- Correct storage conditions: Sealants and fillers must not be left overnight or too long in the elements. For example, not left in direct sunlight or outside in freezing conditions for long periods. Store in containers at general room temperature.

- All surfaces where strip PIB is laid must be dry, clean and dust free to ensure an adequate bond/seal is made against the substrates.

- In wet conditions, the release paper should be removed as soon as possible to ensure it does not absorb moisture. If left too long it will tear and become difficult to remove.

Ensure Tata Steel guidelines for the correct specification of strip PIB sealants are followed (eg, correct size for the application, specification and supply).

Wall sealants and fillers

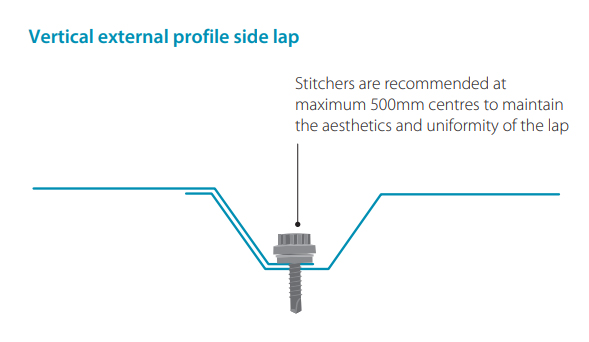

Vertical external profile: The end laps of the external weathering profile of the vertical Trisobuild® systems do not require sealant. The side laps of the vertical external weathering profile also do not require sealant, but should be stitched at a maximum of 500mm centres.

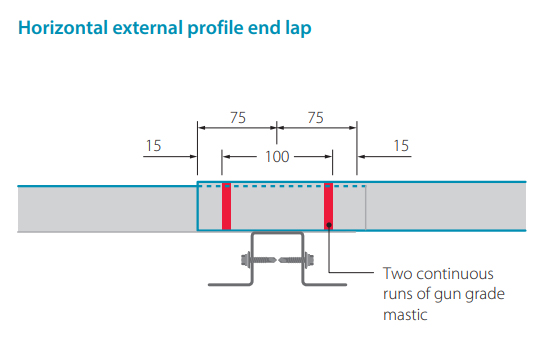

Horizontal profile: The end laps of the external weathering profile of the horizontal Trisobuild® systems require two runs of gun-applied solvent release sealant. Ensure the continuity and the effectiveness of the seal. The two lines of sealant must be placed between the sheets before fixing: one row 10mm from both the sheet ends at the top and bottom of the lap (ensure space is left for compression).

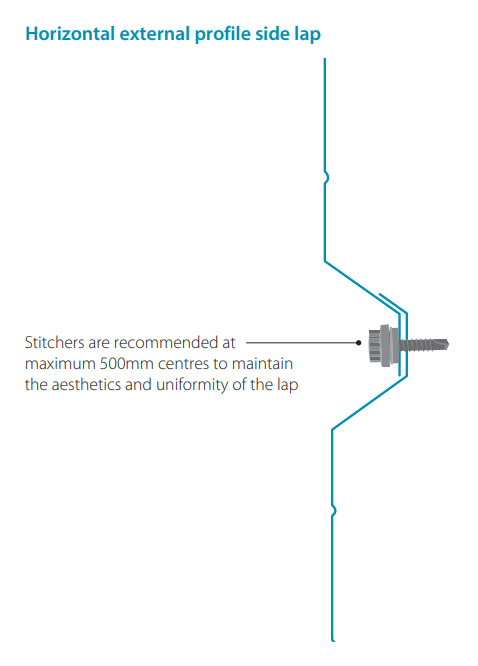

The side laps of the horizontal external weathering profile do not require sealant, but should be stitched at a maximum of 600mm centres.

For external weathering black EPDM, MP or Superseal vented profile fillers should be located between the external profile and the cover flashing to provide continuity of weather seal and to prevent access by insects and small birds. These shaped fillers should be sealed at their base with a run of 9 x 3mm high grade butyl strip sealant.

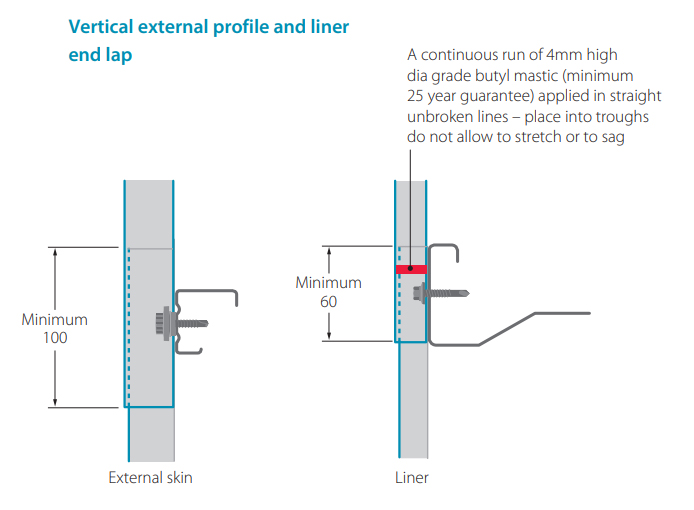

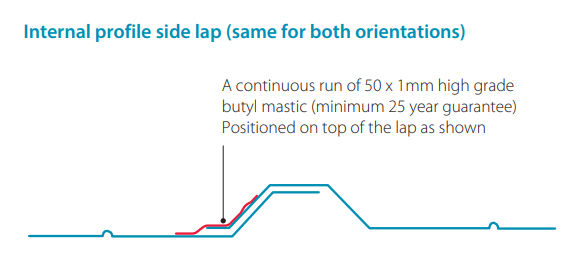

The liner profile should have both the side and end laps sealed. The end laps sealed with a 4mm diameter high grade butyl mastic (min 25 years guarantee). The side lap sealed with a

50 x 1mm high grade butyl mastic (minimum 25 years guarantee) positioned on top of joint.

For liner profile ends at eaves base of wall, white EPDM, MP or Superseal profile fillers should be located between the profile's internal profile and the internal cover flashing to provide continuity of air seal. These fillers should also be sealed top and bottom on a run of 9 x 3mm high grade butyl strip sealant.

All sealants can be sourced from either:

Premier Sealants (White strip) - T: +44 (0) 1724 864100

EJOT UK Limited (Blue Strip) - T: +44 (0) 1977 687040

SFS intec Ltd (Pink Strip) - T: +44 (0) 113 208 5500.

All fillers can be sourced from either:

Premier Sealants - T: +44 (0) 1724 864100

EJOT UK Limited - T: +44 (0) 1977 687040

Typical wall fastener layouts for standard profiles:

| Profile | Main Fixings (sheet ends) | Main Fixings (intermediate) | Side lap fixings |

| 13.5/3 | Every third trough | Every third trough | 500mm vertical, 600mm horizontal |

| C32 | Every trough | Every other trough | 500mm vertical, 600mm horizontal |

| C32MR | Every trough | Every other trough | 500mm vertical, 600mm horizontal |

| C46 | Every trough | Every trough | 500mm vertical, 600mm horizontal |

More fasteners may need to be included to resist negative wind load forces. It is recommended that you speak to our Technical Department to discuss the specific loading and support structure on your project to ensure that sufficient restraint is being provided.

We hope this blog has provided useful advice on how to achieve effective seals at overlap joints and how to further protect your building against water penetration and air-tightness.

Please contact our Technical Department for further details on sealants and fillers or use our online specification tool to help you create the right specification for the performance that suits the needs of your project. Doing this will give you peace of mind that cladding components are compatible and perform together as a system.