Sir Robert McAlpine's appointment as a main contractor supporting Tata Steel UK’s decarbonisation plans at Port Talbot is the latest chapter in their involvement at the steelworks that stretches back to the late 1940s.

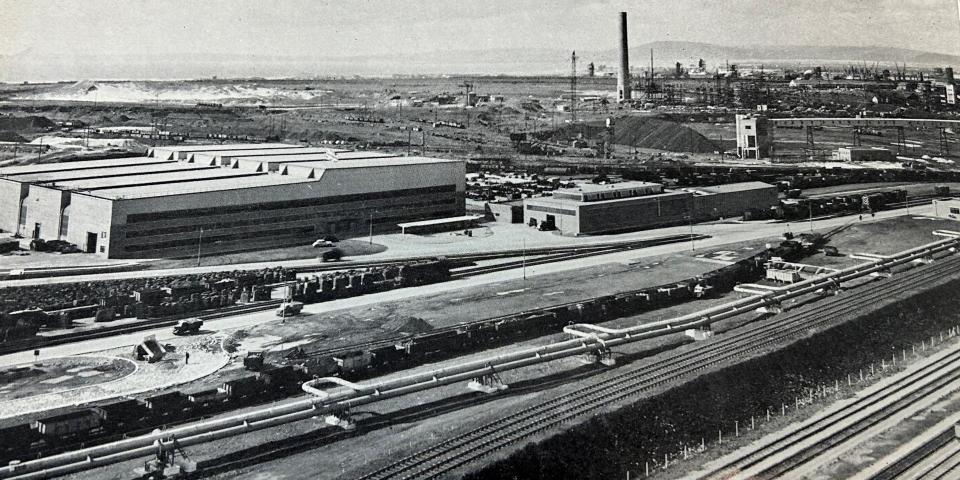

The reconstruction work at the site was one of the biggest post-war enterprises in the country, with a value of £60m.

Sir Robert McApline (SRM) were then responsible for the most radical of the alterations to the steelworks, all of which had to be completed while the plant remained in full production, a factor which added hugely to the project’s complexity.

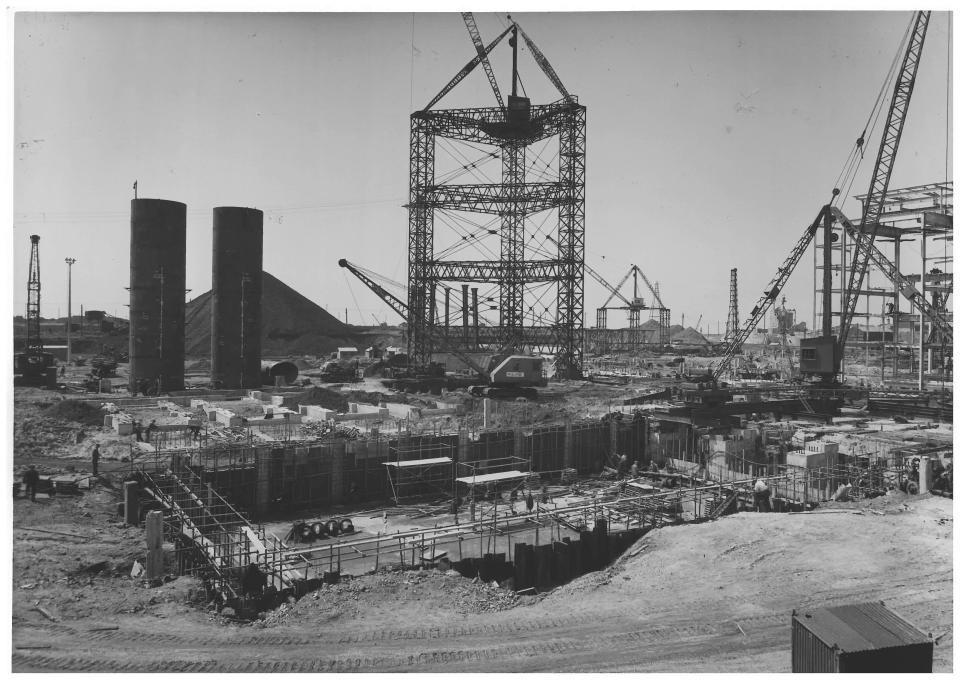

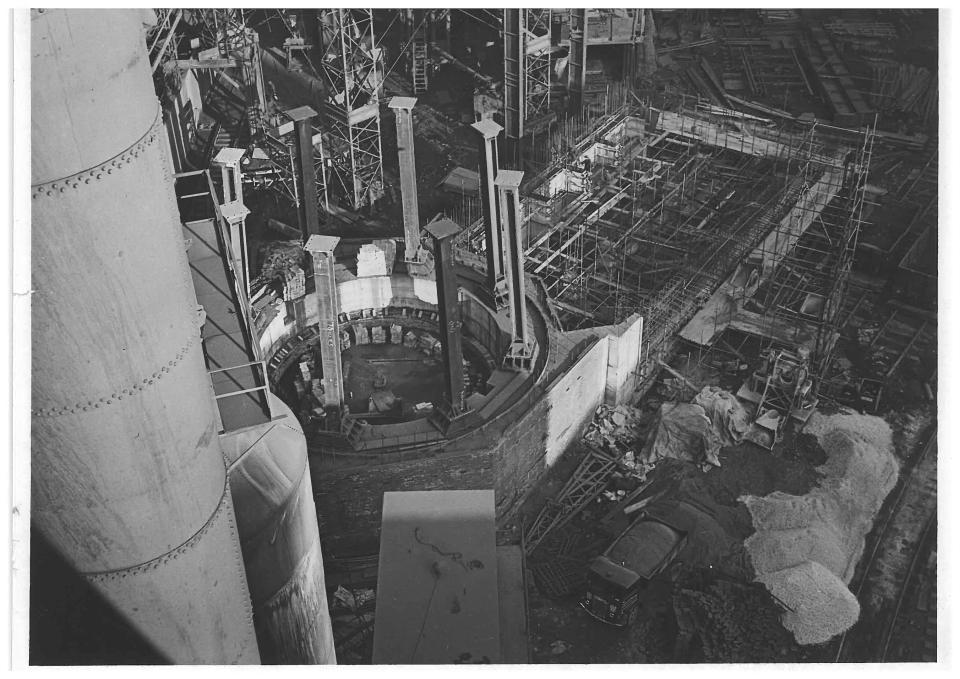

In what was a huge civil engineering undertaking, works included the foundations for blast furnaces, one of which was the largest in the world at the time, delivery of a reinforced concrete gantry for ore transportation, construction of a power house and the diversion of a river, a main sewer and British Railway lines. A quay wall was also extended to provide more berthing space at the works’ iron ore quay.

With each of the plant’s operations integrated and dependant on each other, ensuring all the work was carried out to schedule was vitally important.

The fact that all SRM's work was delivered on time or early was only possible thanks to our close collaboration with the plant’s production team and a determination to avoid any delay, despite the formidable challenges involved. It is a way of working and an approach to overcoming challenges which will be familiar to our modern day project teams.

The national press reported at the time:

“…The immense significance of the work carried out by Sir Robert McAlpine and Sons Ltd cannot be overstressed. It consisted of designing, enlarging and modernising the existing Margam works to increase output for Abbey Strip Mill.

“Extending British Railways docks tracks, together with viaducts, bridges, embankments and the tripling of the existing capacity constructing eight miles of new works sidings and relaying all works railway. The construction of reinforced concrete work to two blast furnaces, power and boiler house, wharf extensions, half a mile concrete ore bunkers, transfer car bridges and many ancillary buildings.”

By the 1960s the Abbey Works, as the original Margam plant came to be known, was Europe’s largest steelworks and the biggest single employer in Wales, with a labour force of 18,000.

Notes to Editors:

For further information, please contact:

Arnaud Pelle: arnaud.pelle@srm.com

Tim Rutter: tim.rutter@tatasteeleurope.com +44 (0)7850 990755

About Sir Robert McAlpine www.srm.com

- Sir Robert McAlpine is a family-owned building and infrastructure company operating across the UK. We have been proudly building Britain’s future heritage since 1869.

We are honoured to have worked on some of the country’s most iconic buildings and projects. - The values at the heart of our operations include a commitment to the highest standards of safety, quality, engineering excellence, sustainability, and a steadfast focus on the needs and aspirations of our clients.

- We champion equality and welcome a diversity of talent to our inclusive family culture.

- Working in partnership with our clients, we aim to make a positive impact on the communities and the environment in which we operate, as we construct a better world for future generations.

About Tata Steel

- The Tata Steel Group has been named one of the most ethical companies in the world, and is among the top producing global steel companies with an annual crude steel capacity of 34 million tonnes.

- Tata Steel in the UK has the ambition to produce net-zero steel by 2045 at the latest, and to have reduced 30% of its CO2 emissions by 2030.

- Tata Steel is the largest steelmaker in the UK with primary steelmaking at Port Talbot in South Wales supporting manufacturing and distribution operations at sites across Wales, England and Northern Ireland as well as Norway, Sweden, France and Germany. It also benefits from a network of international sales offices around the world.

- Tata Steel employs more than 8,000 people and has an annual crude steel capacity of 5 million tonnes, supplying high-quality steel products to demanding markets, including construction and infrastructure, automotive, packaging and engineering.

- Tata Steel Group is one of the world's most geographically-diversified steel producers, with operations and a commercial presence across the world.

Follow us on social media