EN-Construction-RoofDek-MagiZinc®

What is MagiZinc®?

MagiZinc® is an innovative replacement for conventional galvanised steels. It provides superior corrosion protection even in harsh environments.

MagiZinc® is an innovative replacement for conventional galvanised steels. It provides superior corrosion protection even in harsh environments.

A product that performs...

MagiZinc® provides superior protection, extending product life and offering excellent formability and weldability. It is a hot-dip zinc coating alloyed with magnesium and aluminum.

A chromium-free passivating agent makes MagiZinc® compatible with common paint.

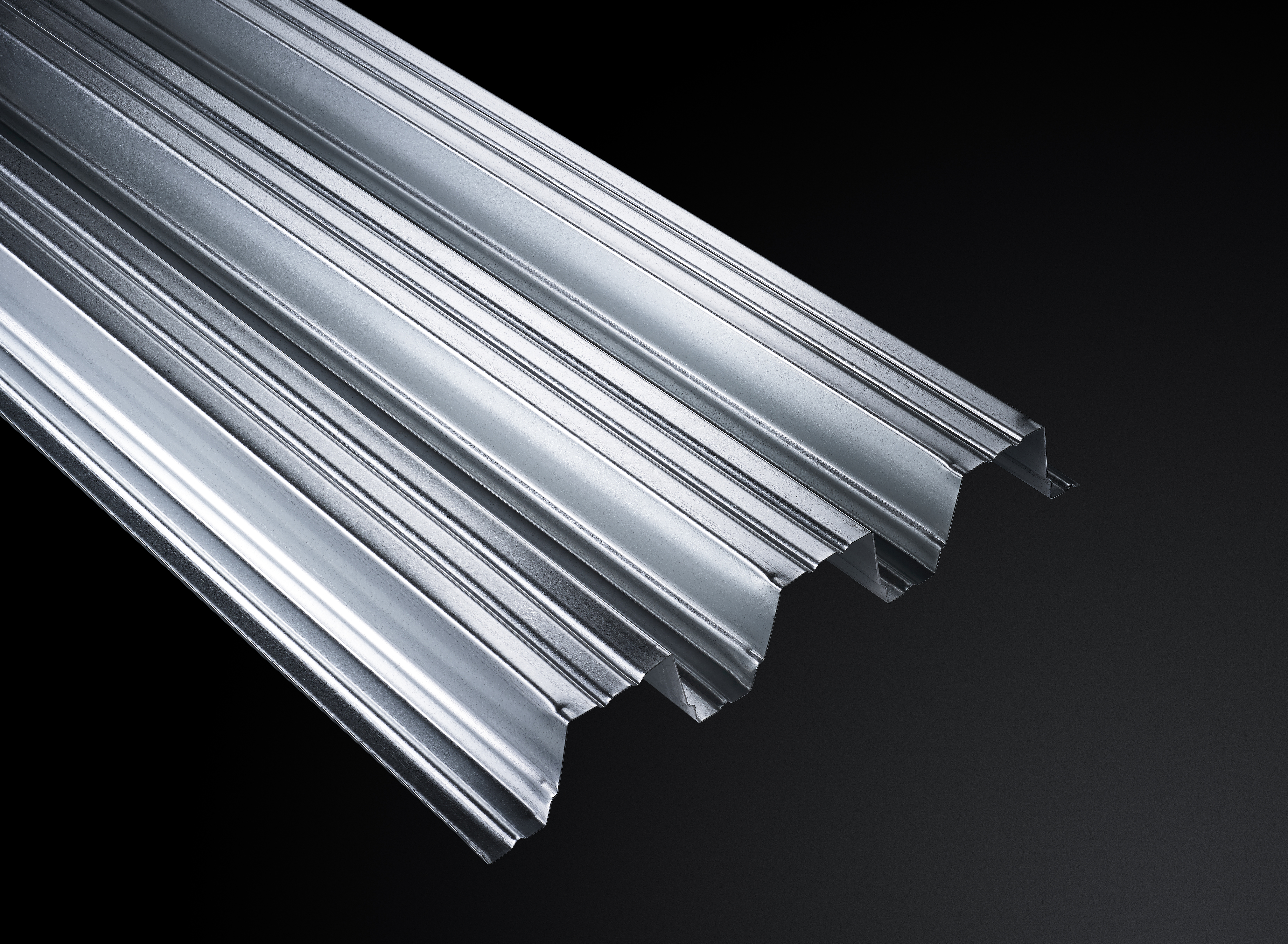

RoofDek MZ - Our structural RoofDek product with a 140g/m2 MagiZinc® coating weight.

Why use MagiZinc® on our RoofDek products?

The testing work undertaken on our roofing and floor decking products with the MagiZinc® coating shows an improved product performance over our standard galvanised coating.

Our RoofDek® MZ product has a lower whole life carbon performance when compared with standard Z275 galvanised coating. Our RoofDek® MZ products have lower coating embodied carbon when compared with standard Z275 galvanised coating.

We have built up a significant amount of test data on our Magizinc® products which provides evidence for improved product performance through the life of your project.

Our RoofDek® MZ product delivers a 37% reduction in coating CO2 when compared with Z275 galvanised coating. The coating process for our MZ products requires fewer resources but delivers improved product performance. Our UK supply chain reduces risk and increases security of supply. Tata Steel has over 60 years experience of galvanising and coating steel.

EN-Construction-Product-RoofDek - D60 | Structural profile specification

RoofDek D60 is part of the shallow deck profile range which enables designers to find the balance between efficiency, aesthetics and structural performance.

| Profile | Material | Gauge and finish (mm) | Weight (kg/m2) | Load/Span maximum single span (mm) | Load/Span maximum double span (mm) | Minimum self curve (m) | Minimum Factory curve (mm) | Cantillever (mm) |

|---|---|---|---|---|---|---|---|---|

| D60 | Steel | 0.70 Interior Liner & Galvatite | 8.34 | 3022 | 3772 | 70 | - | 756 |

| Steel | 0.90 Interior Liner & Galvatite | 10.73 | 3348 | 4489 | 80 | - | 837 | |

| Steel | 1.20 Interior Liner & Galvatite | 14.32 | 3672 | 4923 | 85 | - | 918 | |

| Aluminium | 0.90 Stucco | 3.72 | 2300 | 3060 | 70 | - | 575 | |

| Aluminium | 1.20 Mill | 4.96 | 2542 | 3408 | 80 | - | 635 |

Notes

1. When RoofDek is supplied with Colorcoat HPS200 Ultra® pre finished steel, the above load span tables do not apply. Please contact our technical team for the load span tables in this instance.

2. Calculations accord to Eurocode, however a fixings check is also required.

3. Load table is based on the deck bearing onto 100mm min. flange steel beam.

4. Load spans calculated to Eurocode 3 and 9.

If you have any questions or for further information click here to contact us.

EN-Construction-Product-RoofDek - D60 | Download BIM objects

BIM: The way you want it

The DNA Profiler has been designed to allow you to access Tata Steel’s product information (3d parametric objects & data) how you want, when you want, to the level of detail you want, in the format you want.

| Product Name | Link |

|---|---|

| RoofDek D60 0.70mm steel | BIM DNA Profiler |

| RoofDek D60 0.70mm steel - Colorcoat | BIM DNA Profiler |

| RoofDek D60 0.70mm steel perforated | BIM DNA Profiler |

| RoofDek D60 0.70mm steel perforated - Colorcoat | BIM DNA Profiler |

| RoofDek D60 0.90mm Alu | BIM DNA Profiler |

| RoofDek D60 0.90mm Alu perforated | BIM DNA Profiler |

| RoofDek D60 0.90mm steel | BIM DNA Profiler |

| RoofDek D60 0.90mm steel perforated | BIM DNA Profiler |

| RoofDek D60 1.20mm Alu | BIM DNA Profiler |

| RoofDek D60 1.20mm Alu peforared | BIM DNA Profiler |

| RoofDek D60 1.20mm steel | BIM DNA Profiler |

| RoofDek D60 1.20mm steel perforated | BIM DNA Profiler |

In addition to our DNA Profiler, you can access our BIM content at BIMobject.com

| Product Name | Link |

|---|---|

| RoofDek D60 (Shallow Deck) | BIM Object |

If you have any questions or for further information click here to contact us.

EN-Construction-Product-RoofDek | RoofDek quick selector

The increasing complexity of roof decking projects makes any software aimed at easing the process very welcome indeed.

To aid this, Tata Steel introduced the RoofDek quick selector, a web based structural analysis tool. It allows a user to rapidly select the most appropriate deck for the application and structural requirements using a PC or tablet, including iPad.

The software provides an optimised RoofDek specification, and it also allows the user to choose an alternative RoofDek profile. The RoofDek quick selector page contains pre-populated span and load figures as an example, but users can then modify these to their own requirements to find the right decking profile for a given project. All calculations are carried in accordance with Eurocode 3 on one screen and may be printed out as a record of the design.

The RoofDek quick Selector augments Tata Steel’s suite of roof decking software.

If you have any questions or for further information click here to contact us.

EN-Construction-Product-RoofDek | Load span tables

Eurocode load span tables and section properties.

For more information on our RoofDek Load Span parameters please download the below brochure.

EN-Construction-Product-RoofDek | RoofDek Analysis Software, Powered by Tekla Tedds

Our RoofDek Analysis Software has been created in partnership with leading software developer, Trimble, using their widely-adopted structural calculation software, Tekla Tedds, as the platform for the deck analysis software.

This software compliments and enhances our RoofDek quick selector, allowing users to conduct full deck analysis.

It also completely satisfies the need to comply with Eurocode 3 Design of Steel Structures and Eurocode 9 – Design of Aluminium Structures.

Users are able to input up to four spans, two of which can be cantilevers. Extended end laps can be included as internal supports. Thickness of deck can be varied each side of extended end laps.

If you have any questions or for further information click here to contact us.

EN-Construction-sustainability-optemis-carbon-lite

The launch of Optemis Carbon Lite is an important step in our ongoing decarbonisation journey. It demonstrates our progress and represents a unique solution for customers in the form of a flexible, lower CO2 steel offering.

Optemis Carbon Lite is a fully certified in-setting scheme with CO2 savings achieved from implemented projects, verified by a 3rd party auditor, DNV, and credited to our CO2 bank. Our continued commitment to decarbonisation means reductions in CO2 emissions can now be passed on to our customers, enabling them to achieve immediate Scope 3 emission savings.

Revenues generated from the sale of Optemis Carbon Lite declarations are used to fund additional decarbonisation projects, generating further CO2 savings to be verified by DNV and speeding up our decarbonisation efforts.

By buying Optemis Carbon Lite from Tata Steel UK we, and our customers, will be actively contributing to a reduction in atmospheric CO2.

EN-Construction-Product-RoofDek | Design support

We maintain a friendly technical help desk which is freely available to all architects, engineers and contractors to assist with all aspects of RoofDek and liner tray design. The services we offer include:

Specification service - Our RoofDek team are able to provide a comprehensive specification service. Assistance in creating NBS specifications for RoofDek and trays can be provided to ensure the correct deck or tray is specified for the right application.

Design calculations & diaphragm design - To assist the specifier, the team are able to provide design calculations for live, dead, wind and snow drift loads and where required diaphragm design calculations.

Sound absorption and reduction - RoofDek perforated decking provides excellent sound absorption characteristics, our technical team can provide details of systems tested for both absorption and reduction. We also offer indicative acoustic calculations on differing build ups.

Roof Safety - Our technical department can provide details of non fragility performance of the RoofDek itself and the use of fall prevention and fall arrest systems on RoofDek roofs.

Inhouse CPD seminars - Primarily aimed at engineers and architects, these free seminars last around 50 minutes, ending with a question & answer session and are delivered by our experienced regional teams.

Topics include:

- Structural roof deck in construction

- Composite floor deck in construction

- Sustainable steel cladding refurbishment solutions

- Factory tour of Insulated panel lines

To request a CPD seminar please click here.

If you have any questions or for further information click here to contact us.

EN-Construction-Product-RoofDek-D60-downloads

Select from below downloads

EN-Construction-Approval_or_Certificate-CE DOP RoofDek D60 Galv Colorcoat HPS200 Ultra

CE DOP RoofDek D60 Galv Colorcoat HPS200 Ultra®

EN-Construction-Approval_or_Certificate-UKCA DOP RoofDek D60 Colorcoat HPS200 Ultra

UKCA DOP RoofDek D60 Colorcoat HPS200 Ultra®

EN-construction-Building Systems UK full range at a glance

Building Systems UK full range at a glance

EN-Construction-Certificate-BES6001-UK products

BES 6001 Certificate UK products

EN-Construction-Book a CPD

We offer a range of face to face and online CPDs aimed at Engineers and Architects

These free seminars can be booked at any time between 9am and 5pm. Our online webinars can all be delivered via Skype for Business and Teams, but we can consider other platforms if this will not work for your practice.

Below outline the CPDs we have available - Book yours today

- Decarbonising your structural hollow section designs

- Essentials of Structural Hollow Sections

- Welded Joints in Tubular Steelwork - Eurocode 3 Part 1-8

- Concrete Filled Hollow Sections - Composite Design – Eurocode 4

- Composite Floor Deck in Construction

- Structural Roof Deck in Construction

- Specifying metal clad envelope systems in accordance with ADB2 of the building regulations and the value of large scale system testing

- RIBA 2030 climate challenge: How steel building envelope solutions contribute

- Pre-finished steel standing seam systems for roof & wall cladding

- CDM regulations 2015 and their impact on steel building envelope specification.

- Steel building envelope systems for non-domestic buildings

- Steel for roof and wall cladding

EN-Construction-NBS-specification-tab-Roofdek

EN-Construction-Product-RoofDek | RoofDek installation videos