A composite floor deck provides a structurally strong and lightweight floor, whose efficient use of materials provides a host of benefits in terms of building performance and sustainability. They are usually specified for commercial and industrial projects, though they can also feature in residential applications.

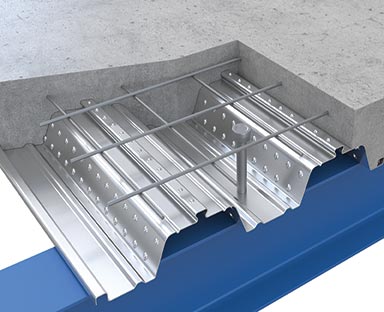

The typical components of a composite floor are a steel profile (which might itself be called a ‘deck’), usually trapezoidal in shape. Shear studs connect the profiles, and a poured concrete cover with mesh reinforcement provides the finished surface.

How does the steel profile affect composite floor deck performance?

Steel profiles come in a variety of depths, which dictate the depth of concrete cover required and the spans that the composite deck can achieve. The width of the profile impacts on the ease of handling on site, and once the profile is installed it can act as a working platform.

The depth of the profile can change whether it is fixed to the top or bottom flange of a supporting beam, which can help with optimising the slab depth zone to avoid using too much concrete while still achieving the required fire, acoustic and thermal mass performance.

At first glance, steel profiles might all look like a similar trapezoidal shape. However, they are carefully optimised, depending on application and to deliver desired strength and spans. Examples of this optimisation include the radius to which trough corners are rounded, and how the shear studs are accommodated.

Also, some profiles ‘stack’ better within each other, meaning more profiles can be transported on a single lorry to reduce total road miles.

What are some of the advantages of a composite floor deck?

A composite floor deck is inherently lighter and faster to construct than a precast concrete floor (you can read a more in-depth blog post about the two types of deck here). Lighter floor structures impose less load on the building structure, meaning lighter foundations can be used. The composite deck therefore promotes overall savings in material use.

Composite decks provide acoustic performance, fire performance, and efficient thermal mass. Not only that, but the steel profile can be factory finished in a range of colours and options to suit the required aesthetics and the harshness of the internal environment (such as being used over a swimming pool).

Tata Steel’s ComFloor® deck range, for example, has paint applied before the roll of steel is formed into profiles. This achieves a higher level of finish than can be achieved with post-painting. The ComFlor® range is also manufactured entirely using UK-produced steel.

Find out more about Tata Steel’s seven unique ComFlor® composite deck profiles, including low profile and deep deck options designed for specific applications.