For the construction industry there is a much bigger opportunity and responsibility to contribute to sustainability. This involves looking at the whole life-cycle and the true cost and impact of the materials we use, from sourcing to the end of life and beyond.

Sustainability is an issue that affects us all. We all have a part to play in trying to save resources for future generations and in achieving a greener future. On an everyday level, this could mean looking at the way we do things, like remembering to recycle milk bottles or not leaving the tap running.

For the construction industry, however, there’s a much bigger opportunity and responsibility to contribute to sustainability. This involves looking at the whole life-cycle and the true cost and impact of the materials we use, from sourcing to the end of life and beyond.

Making the right material choices

Material selection is, of course, a vital part of the construction process, and has the potential to make a huge difference on the environmental footprint of a project. Quite often, the carbon impact of a material is considered up to the point of the building handover. However, this cradle-to-gate approach to assessing the environmental effect of a building does not provide a complete picture. It does not take into account the energy used during the building’s operation, and just as importantly, at the end of its life.

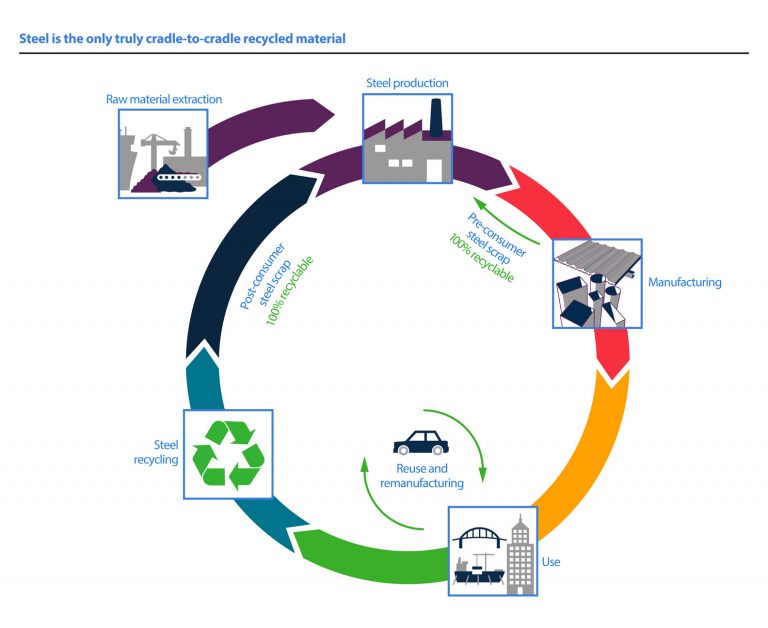

This is where life-cycle thinking comes into play. It looks at the influence of materials across their entire lifespan, including material extraction, manufacture, transport, construction, use, maintenance, and end of life. By not taking a life-cycle perspective, we may be making the wrong resource decisions in the long-term. With this perspective in mind, the strengths of steel become apparent.

Firstly, steel is incredibly durable and, for a given application with nominal maintenance, can deliver ‘use’ measured in tens of years. There are a number of steel applications out there today which can be measured in centuries. This is a key point in terms of resource use. The first rule of saving resources is not to use them in the first place, and the durability of steel over long time spans contributes to this saving.

Advances in steel design are also helping to reduce the resources required for a given design through the use of higher strength steels, which deliver a performance with less steel than those with lower strengths. At the end of the life of a project or application it is, however, where steel can again contribute to resource optimisation.

Figures vary, but almost all steel is recycled and there is no limit to the amount of times steel can be recycled. One important fact here is that steel can be recycled without loss of quality and can be used for the same or higher purpose than its previous incarnation.

With the advent of increasingly circular economic approaches to construction design, steel has an important role to play beyond recycling. Again, the durability of steel means that it is extremely well suited to refurbishment or reuse. More work is required across the supply chain to ensure we are maximising the resource opportunity available (design for disassembly, standardisation and so on), however steel really can be the ‘engine of the circular economy’.

Partnering for the future

So, what is the best way to move towards a more holistic approach to sustainability?

Life-cycle thinking is about being more forward-thinking and not just giving consideration to what is happening now, but what is going to happen at the end of a building’s life. While the design stage of a project may seem like the natural place to begin thinking about the environmental influence of a building, tightened timescales can often mean not enough time is allocated to this thought process.

At Tata Steel, we believe in early collaboration and building partnerships to provide the necessary education and understanding in advance. This can help us provide life-cycle information to allow us to make better decisions on material and product selection when researching specifications. By moving away from transactional relationships and utilising the supply chain expertise of partners, we can work together as an industry to create a greener, more sustainable future.