The loss or dissipation of sound energy in passing through a material or on striking a surface.

ABSORPTION – The loss or dissipation of sound energy in passing through a material or on striking a surface. The term may also refer to the property of a material to damp sound energy.

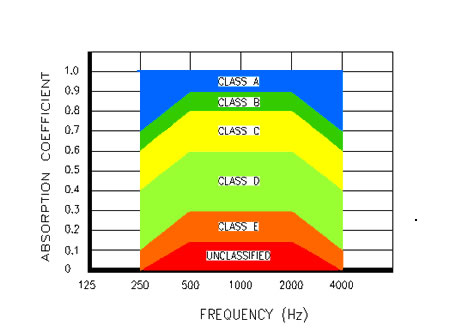

ABSORPTION COEFFICIENT – The fraction of energy absorbed on striking any surface, stated as values between 0 and 1.0. If a surface absorbs no sound its coefficient of absorption is 0. If 100% of sound is absorbed the coefficient is 1.0. In laboratory tests values greater than 1.0 can be achieved due the total area of the trapezoidal profile shape being greater than the plan area. Absorption is frequency dependent, lower frequencies are not absorbed as well as higher frequencies.

SOUND ABSORPTION CLASSIFICATION – BS EN ISO 11654:1997 Acoustics.

Ratings for Sound Absorption classifies materials into bands, Class A to Class E. Insulation achieves Class A, the highest level of absorption, whereas plain un-perforated steel sheet reflects sound with no absorption and is unclassified.

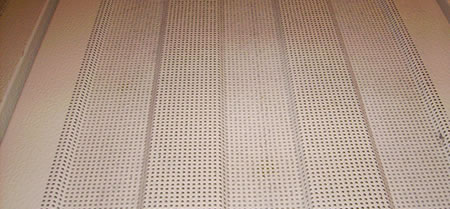

To enhance acoustic absorption decks can be supplied perforated. Fully perforated this would reduce the structural strength of the deck, therefore perforation areas are limited to the side webs, as indicated in this photograph of RoofDek D100:

Structural trays offer a wider flat soffit thus enabling a greater perforation area, which achieves the best acoustic absorption result. Note a plain band remains at the tray side laps to allow possible attachment of hangers for services:

Perforating the liner sheet allows sound to penetrate into the cavity, to be absorbed into the soft insulation, formed from trough fillers, or rigid slab at 45Kg/m3 minimum density. Insulation to be tissue faced, available white or black, to prevent fibres detaching and penetrating the internal environment.

Absorption tests have been conducted on our range of perforated decks and trays at Salford University Acoustics Laboratory, with and without trough fillers.

As a result of these tests, Tata Steel's RoofDek and Structural liner trays have been classified in the table below: