By creating the tools to help meet budgets and timescales, construction product manufacturers can ease some of the pressure on contractors who are pricing wall and roof systems.

Contractors do not need reminding of the pressures placed upon them when it comes to delivering high quality building envelopes. Increased awareness of the performance gap means greater scrutiny of the finished building to see if it achieves the design intent. Meanwhile, the on-site team tasked with delivering that end product is drawn from a shrinking pool of skilled workers.

Nevertheless, budgets and timescales must be met, which puts the onus on speed, accuracy and collaboration. By creating the tools to help achieve those things, construction product manufacturers can ease some of the pressure on contractors who are pricing wall and roof systems.

Collaboration in building envelope design

Theoretically, the development of building information modelling (BIM) has improved information sharing and made collaboration on projects easier. But collaboration is only as strong as the quality of the information received.

The level of adoption of BIM across industry remains varied, meaning individual working approaches and the flow of information also varies. Whatever level of ability a contractor has achieved in their adoption of BIM, the quality of digital models received from designers has to be good - including information sourced directly from product manufacturers.

Similarly, for contractors who assume design responsibility on projects, the quality of their output is highly dependent on the information provided by manufacturers. Being able to offer an appropriate level of detail in the model at the right time, and in the right format, affects the ability of contractors to tender for projects - especially ones where a certain level of BIM is mandated.

How procurement can benefit from adopting digital solutions

Without the right quality of information, producing schedules, quoting prices and procuring materials takes longer to carry out accurately.

Ideally, a price is submitted based on a complete system build-up offered by a single manufacturer. The system has to be suitable for the project location and backed by a guarantee from the manufacturer. And, of course, the system specification should also be available in the manufacturer’s current product range.

This is where collaboration really comes to the fore. The contractor is relying on either the designer’s digital project model being up-to-date, or on the information received back from a supplier. Based on this, specifications and quotes have to be checked; if there are discrepancies, then alternative products have to be researched and verified to make sure they will perform as required to achieve the design intent.

What if, instead, a digital configuration tool allowed building envelope designs to be thoroughly checked, even with different combinations of components?

About Tata Steel’s COMBINED platform

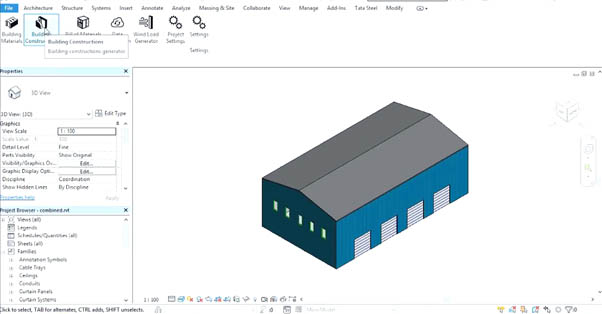

Produced by Tata Steel, the COMBINED platform is a design and configuration tool for building envelope systems. It can be embedded in all major CAD platforms, connecting directly to a centralised database of all Tata Steel building envelope products. That connection gives instant access to a list of available Tata Steel solutions, and the available guarantees, for the project’s location.

It generates material schedules directly from the project’s 3D model, saving time on quotation preparation. Quotations are more accurate, and ordering processes are much easier. Being connected to a database that is updated in real time, our COMBINED platform provides a notification if a product’s characteristics or place in the product range changes.

Design changes can be made and checked quickly, and contractors benefit from knowing that the chosen solution will deliver the expected performance with the full backing of Tata Steel’s Confidex® Guarantee. The COMBINED platform generates all necessary calculation outputs, such as thermal performance and wind loads, quickly and automatically.

Our COMBINED platform also generates a realistic look and feel for the design, thanks to thousands of renders created to accurately represent the Tata Steel product range.

The platform offers a high degree of automation, allowing any number of different design options to be compared quickly and easily, Tata Steel’s technical team remains on hand to address any other queries and provide expert advice where required.

Visit the dedicated COMBINED platform on the Tata Steel website to find out more about how it can assist with designing and procuring building envelope solutions.