MagiZinc® - innovative coating to reduce your total cost of ownership

MagiZinc is an innovative hot-dip zinc coating alloyed with magnesium and aluminium. It reduces tool pollution for improved press shop efficiency whilst delivering superior corrosion protection compared to traditional hot-dip galvanised coatings. MagiZinc improves press shop production metrics by offering the following coating advantages:

- Increased production rates

- Fewer part rejections from galling

- Reduction in down-time for tool cleaning

- Sustainable coating, using less zinc with same corrosion protection and extending product lifetime at equivalent layer thickness.

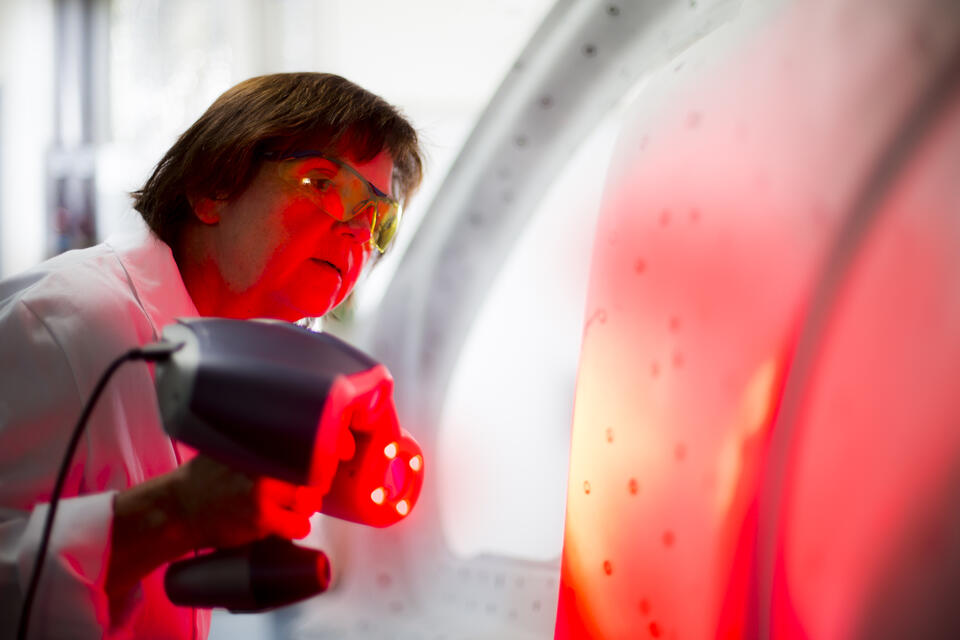

With our MagiZinc TCO Scan our expert team can quantify the total cost of ownership reduction potential that MagiZinc offers for a specific part in your own press line.

MagiZinc Auto offers significant advantages in processing and product performance

Its unique composition allows more robust and efficient forming of complex parts. Compared with GI and GA coatings, it delivers 200% improvement in corrosion protection, achieving these performance increases with less coating.

Our resilient MagiZinc Auto coating is less prone to zinc abrasion, galling and powdering, significantly reducing the typical concerns associated with hot-dipped GI coating and improving press shop KPIs for lost time and scrap. A lower, consistent coefficient of friction and less sensitivity to lubrication quantity reduces process variation and improves the robustness of complex forming processes.

The unique coating composition, with magnesium as the critical alloying element, increases corrosion protection to enable the benefits to be realised with a reduction in coating thickness. Alternatively, where corrosion is a critical performance criterion, Magizinc Auto allows significant improvements to be reached through no additional increase in coating weight. The coating is available in a thickness range of 70-140 g/m2 – with thinner coatings helping to improve welding process stability by reducing spatter and fumes.

MagiZinc Auto is available across our entire automotive forming and high-strength steel portfolio from multiple galvanising lines. It is available in widths of up to 2020mm and coating thickness ranges from 70 to 140 g/m2. MagiZinc is available with Prime Lubrication Treatment, which is a mill-applied surface treatment that boosts lubrication and bonding.

Our material experts are there to support the deployment of our products in your specific application area. For more information contact our MagiZinc experts.

Are you interested in reducing your total cost of ownership?

Since the initial market introduction of the MagiZinc Auto product in 2014, our team of application experts has worked closely with customers to quantify the product's benefits for various different applications.

The depth of experience accumulated over the years, will enable us to support you in determining the benefit of MagiZinc Auto to your process.

For automotive downloads such as brochures, case studies and data sheets, please click below: